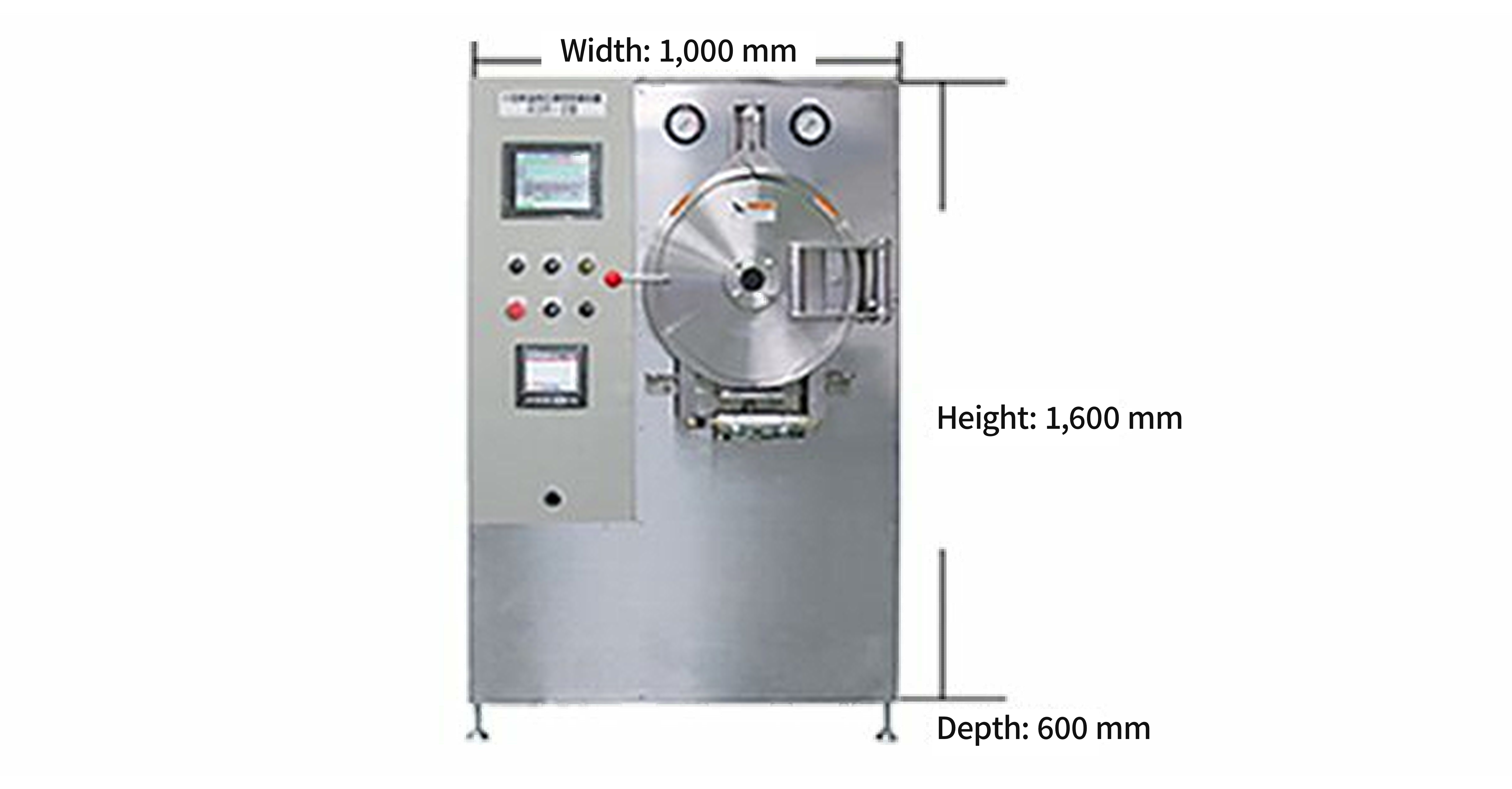

Retort sterilizer ideal for small-volume production or research and development

Overview

- Classified as a compact pressure vessel, this sterilizer does not require installation inspections, annual inspections, or the appointment of a manager.

Features compact, space-saving design. - Simple steam sterilization eliminates the need for extra piping or tanks.

- Adjustable tray height, to sterilize products in containers of all kinds.

Highlights

Broad Container Compatibility

Maximum/Design Pressure

Operating/design pressure: 0.35/0.4 MPa, operating/design temp: 140 °C/152 °C; uniform internal temperature, within ±1.0 °C

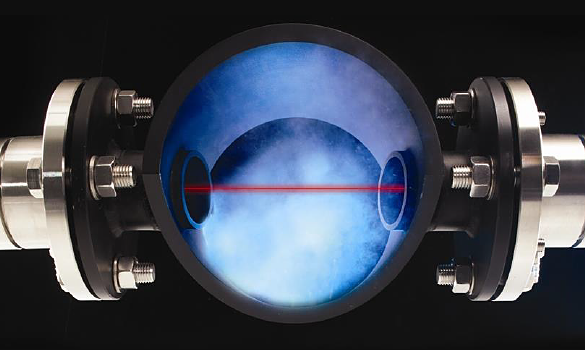

Rapid Heating, Cooling Supported

Cooled by water spray. Products are promptly cooled after sterilization to maintain quality.

Enables Research and Development Based on Real-World Conditions

Incorporates the operating programs used in production equipment for product development and prototyping faithful to actual production conditions.

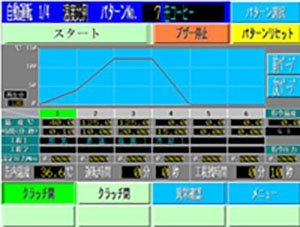

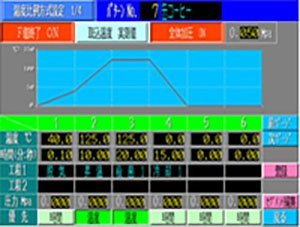

Temperature Program Control

Also serves as an optimal unit for multistage heating.

Allows rapid changes in internal temperature. Contents are sterilized by direct heating using aerated steam, without heating water. Includes ideal functions for gradual heating, multistage cooking sterilization, and pre-sterilization temperature control.

Pressure Control

Pressure can be set based on the form or characteristics of items for sterilization. Eliminates concerns of container damage. Pressure modes include constant (set as needed for each process) or proportional to temperature (pressure control that adds α value to saturated vapor pressure at set or measured temperature for each process). Optionally, uniform pressure and pressure compensation are also available.

Includes F Value Recording

Real-time display of measured values such as internal temperature, product temperature, F value, and pressure. Measurement data is recorded to compact flash memory and can be analyzed on a computer after operation. Can be set to stop automatically when a set F value is reached.

Outstanding Usability

Easily enter operating conditions and control the unit from the touchscreen display.

|

Pattern settings |

|

Register up to 100 patterns. |

|

Program settings |

|

Up to 24-segment programmed operating conditions: mode, temperature, and pressurizing time |

|

Starting operation |

|

Simply select a pattern on the pattern selection screen and press the Start key. |

|

Error display |

|

View error details and check status as needed. |

For product inquiries, please submit the contact form.