Enables real-time remote temperature control

Wireless Data Loggers

Wireless Data Loggers measure temperature periodically and transmit this data wirelessly to enable real-time monitoring from a control system. The DataTrace Micropack RF data logging system combines logging with RF transmission to monitor a broad range of temperatures from -80 °C to 140 °C, and is an ideal way to control temperature in heat sterilization or disinfection, freezing, or refrigeration processes in the food, beverage, pharmaceutical, and other industries.

Highlights

-

- High heat and pressure resistance: -40 to 140 °C, 0–980 kPa

-

Enables measurement of temperature, pressure, and humidity of products and ambient temperature during heat sterilization and disinfection processes involving retorts, autoclaves, fryers, or hot-air sterilization (-80 to 400 °C, depending on sensor type).

-

- Compact (23.2 mm in diameter, 94 mm long, and 66 g)

-

Easily attaches to products for accurate measurement of temperature, pressure, and humidity.

-

- No wires

-

Eliminates measurement errors: no sensor detachment, even in moving processes, and saves time and labor when performing measurements.

-

- Two data display modes

-

Logging data: Data is read and displayed by software after the process

Real-time data: Data currently measured is displayed in the software in real time

-

- User-replaceable battery

-

Batteries last from about six months to one year.

-

- Wide range sensors available

-

An array of sensors are available for various processes or applications.

-

- Measurement up to 400 °C supported in conjunction with thermal barriers

-

- Complete service network in place

-

Service and calibration in Japan are available from Seika partner companies specializing in DataTrace maintenance.

Various demo sensors are also available on loan during calibrations or repairs.

Specifications

| Sensor |  |

|

|

|

|

|---|---|---|---|---|---|

|

Stationary |

Bendable |

High-temperature bendable |

For temperature and pressure |

For temperature and humidity |

|

| Dimensions | 23.2 mm in diameter, 92 mm in length | ||||

| Weight |

66 g |

89 g |

103 g |

114 g |

|

| Material |

SUS316 (body), Ultem (antenna) |

||||

| Sensor |

Thermistor |

Pt1000 |

Strain gauge |

Capacitive |

|

| Sensor diameter |

3.2 mm |

2 mm |

– |

– |

|

| Sensor length |

50.8–152.4 mm |

254–635 mm |

– |

– |

|

| Battery |

Lithium button battery with high heat resistance |

||||

| Battery life |

Normally about 6 months to 1 year |

||||

| Logging capacity |

8,000 data points |

4,000 data pointsー (pressure data) 4,000 data pointsー (temperature data) |

4,000 data pointsー (humidity data) 4,000 data pointsー (temperature data) |

||

| Interval |

11 sec. to 1 hr. (logging only) 2 sec. to 1 hr. (logging + real-time communication) |

||||

| Real-time data transmission interval |

5 sec. to 1 hr. |

||||

| Range |

-40℃~+140℃、-80℃~+140℃ |

-40℃~+400℃ |

0〜980KPa |

0〜100% |

|

| Accuracy |

±0.5(-80℃~-40℃) ±0.2(-40℃~+140℃) |

±0.3℃(-40〜140℃)±0.5℃(140℃〜) |

±4KPa/ ±0.2℃ |

±2%RH/ ±0.2℃ |

|

| Surface pressure | 980KPa | ||||

| Data communication |

Infrared (for logging data), 2.4 GHz ISM band (for real-time data) |

||||

Applications

Retort food industry:

Pouch sterilization, ambient temperature measurement (F value)

Beverage industry:

Temperature measurement in pasteurizers for beverages in cans or glass or plastic bottles, or for cooling temperature after hot-packing

Pharmaceutical industry:

Deep freezer temperature control

Confectionery/baking industry:

Bread or cake dough oven baking temperature control

Manufacturing industries:

Pressure resistance measurement for manufactured cans, verification of temperature distribution of in-house equipment, temperature monitoring for vacuum dryers, temperature monitoring for firing furnaces

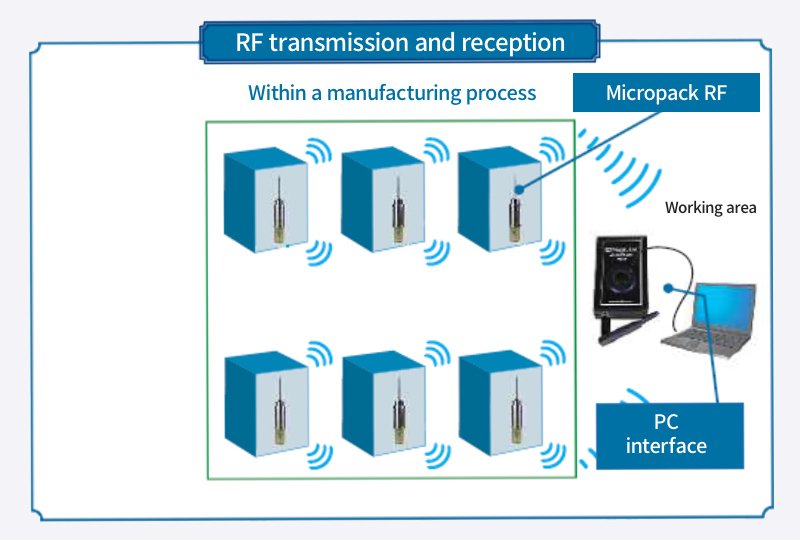

System Elements

・Micropack RF

Standalone logger with built-in antenna and high heat resistance.

・PC interface module

Communication device for connecting loggers to a computer when setting measurement conditions or reading data. Receives radio waves from Micropack loggers and applies the data to software used with this system.

・DataTrace Pro software

Software used to set measurement conditions and read data from loggers. Also enables editing, saving, analysis, and printing of the retrieved logger data.

Meets all requirements of FDA 21 CFR Part 11.

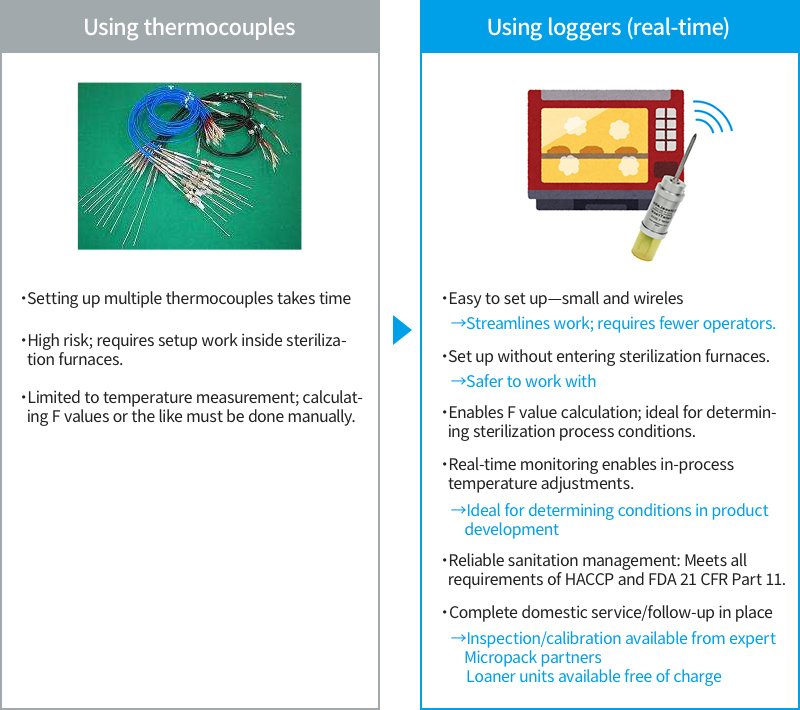

Competitive Comparison

For product inquiries, please submit the contact form.