Clog-free diffuser tubes – also usable in carrier fluidized systems

Ecorator

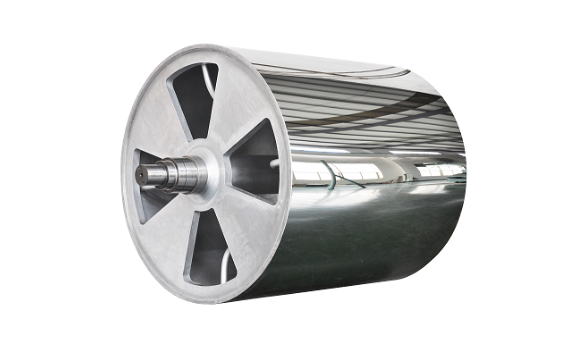

Seika Ecorator diffuser tubes generate a strong air-lifting effect, providing effective aeration and agitation in tanks. Backed by a solid sales record, Seika’s Ecorator units are utilized at sites such as wastewater treatment facilities in the food, chemical, livestock, and semiconductor industries. A simple internal structure prevents clogging and reduces the frequency of on-site maintenance. The ECO-1000 model is also suitable for use in carrier fluidized systems. It features a lower discharge pressure loss than that of membrane or porous diffusers, reducing the blower load and saving energy.

Patent number: 5306187

Highlights

-

- Internal clog-resistant structure

-

Large air outlet cross-section eliminates clogging; can also be operated intermittently

-

- Powerful agitation also works on bottom sludge

-

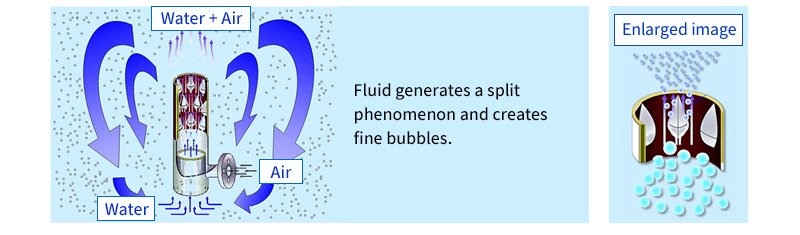

The internal ejector structure ensures ample area for fluid to flow through the tube, enabling a large volume of wastewater or carrier to be drawn in and agitated. Even heavy sludge is evenly agitated.

-

- Highly efficient at dissolving oxygen

-

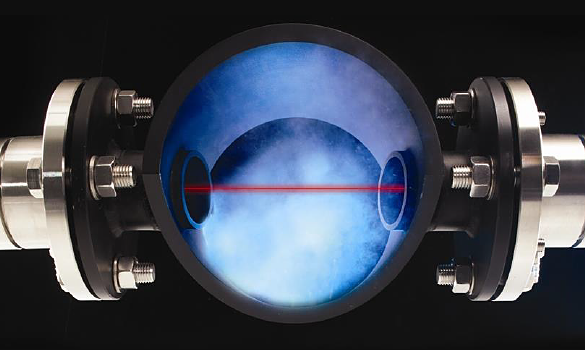

Fine air bubbles are created from a combination of the ejector effect and venturi cutter. Bubbling water drawn in by the powerful air-lifting effect is split into finer bubbles.

-

- Saves energy

-

The diffusers save energy owing to the lighter blower load resulting from highly efficient oxygen dissolving, lower pressure loss, and intermittent operation.

-

- Less frequent maintenance

-

Due to the lack of clogging, there is no need for regular cleaning or replacement, allowing long-term use while maintaining the initial performance level.

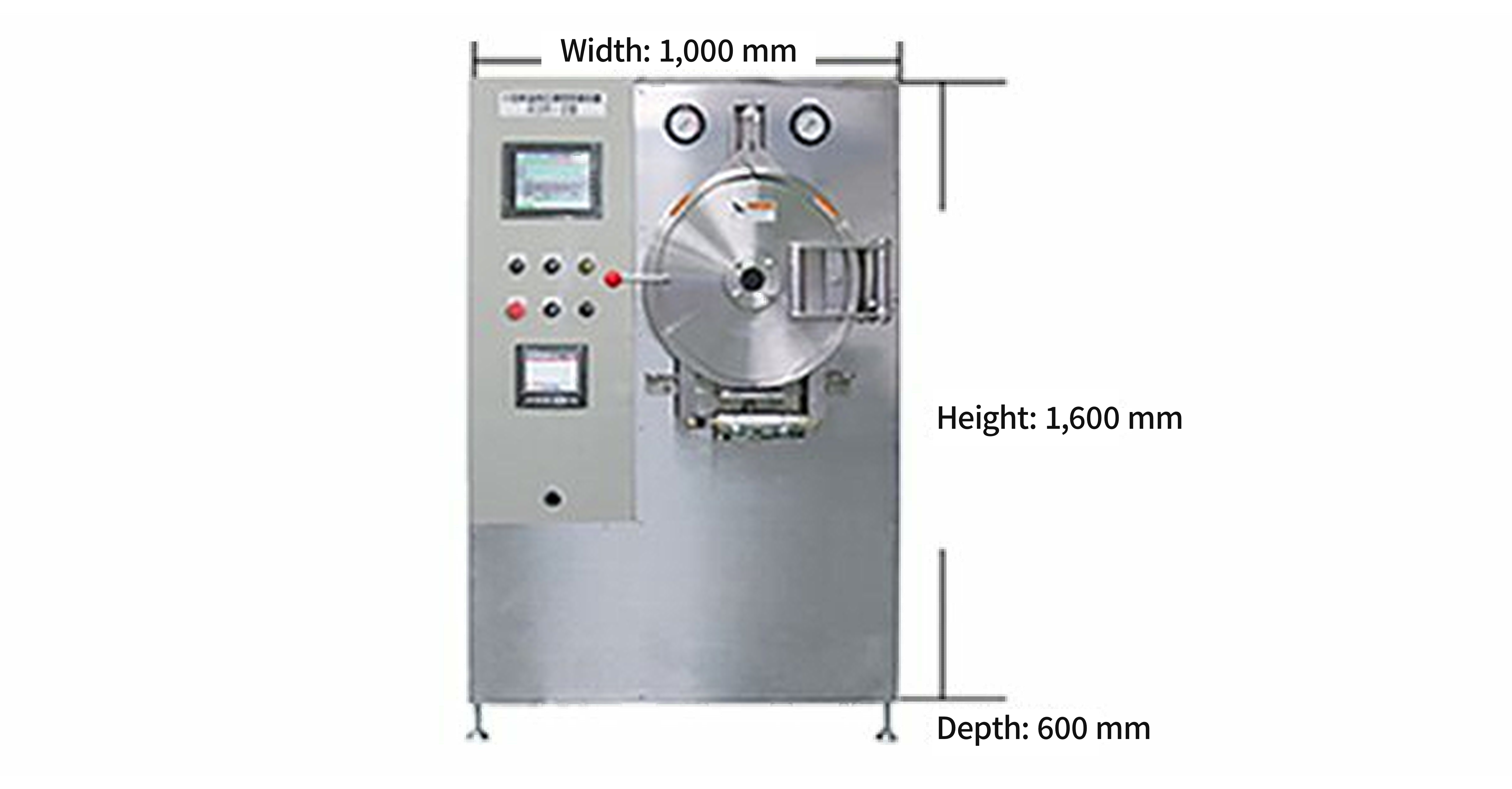

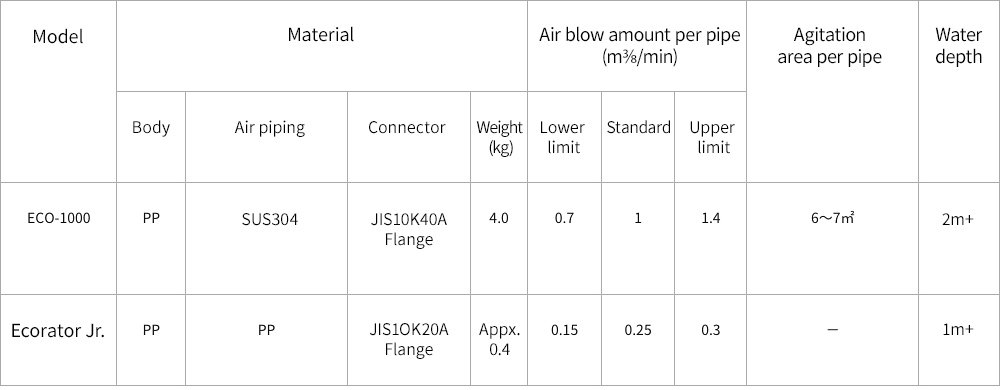

Specifications

Principle

Applications

・Intermittent aeration when inflow is low

・Reduction of accumulated sludge

・Consistent, efficient oxygen dissolving without clogging, which ultimately stabilizes dissolved oxygen levels

・Reduced diffuser maintenance

・Lower electricity costs, resulting from reduced power consumption by aeration blowers

・Simplified piping, enabled through high per-unit processing volume

Competitive Comparison

| Seika Products | Competitive Products | |

|---|---|---|

|

|

|

|

|

Useful life |

10 years or longer (based on past records) |

2–5 years |

|

Clogging |

Does not clog |

Clogs |

|

Sludge buildup |

Powerful aeration and agitation from the ejector effect also works on bottom sludge. |

Sediment inevitably accumulates at the bottom of tanks. |

|

Power consumption |

Pressure loss is lower; allows intermittent operation while maintaining the initial dissolving efficiency, reducing blower load and power consumption. |

Pressure loss is high from the start; subsequent clogging further increases pressure loss. |

|

Installation/piping |

Agitation over a broad per-unit area simplifies piping and reduces installation costs. |

Agitation per unit covers a smaller area, making piping more complex and increasing construction costs. |

For product inquiries, please submit the contact form.