Visually indicates detected gas leaks to allow immediate response.

Handheld Gas Leak Inspection Systems

This handheld gas leak inspection system uses IR and visible light cameras for gas leak imaging.

Through utilization of a Konica Minolta lens design and image processing, high-sensitivity leak detection is performed, followed by overlaying the source of the leak on the image from the visible light camera for leak identification. The system can detect various hydrocarbon gases and is useful in many ways, including simplifying maintenance through digital transformation, helping inspectors check aging equipment, and detecting any leaks after equipment repairs.

When used in conjunction with devices that expand its core functionality, the unit can be used to estimate leak flow rates.

Highlights

- Intuitive tool that allows any user to grasp conditions at the site of a gas leak

- Can also warn users of leaks automatically

- Light and compact for handheld shooting

- Image stabilization is also available, to reduce image noise in handheld shooting

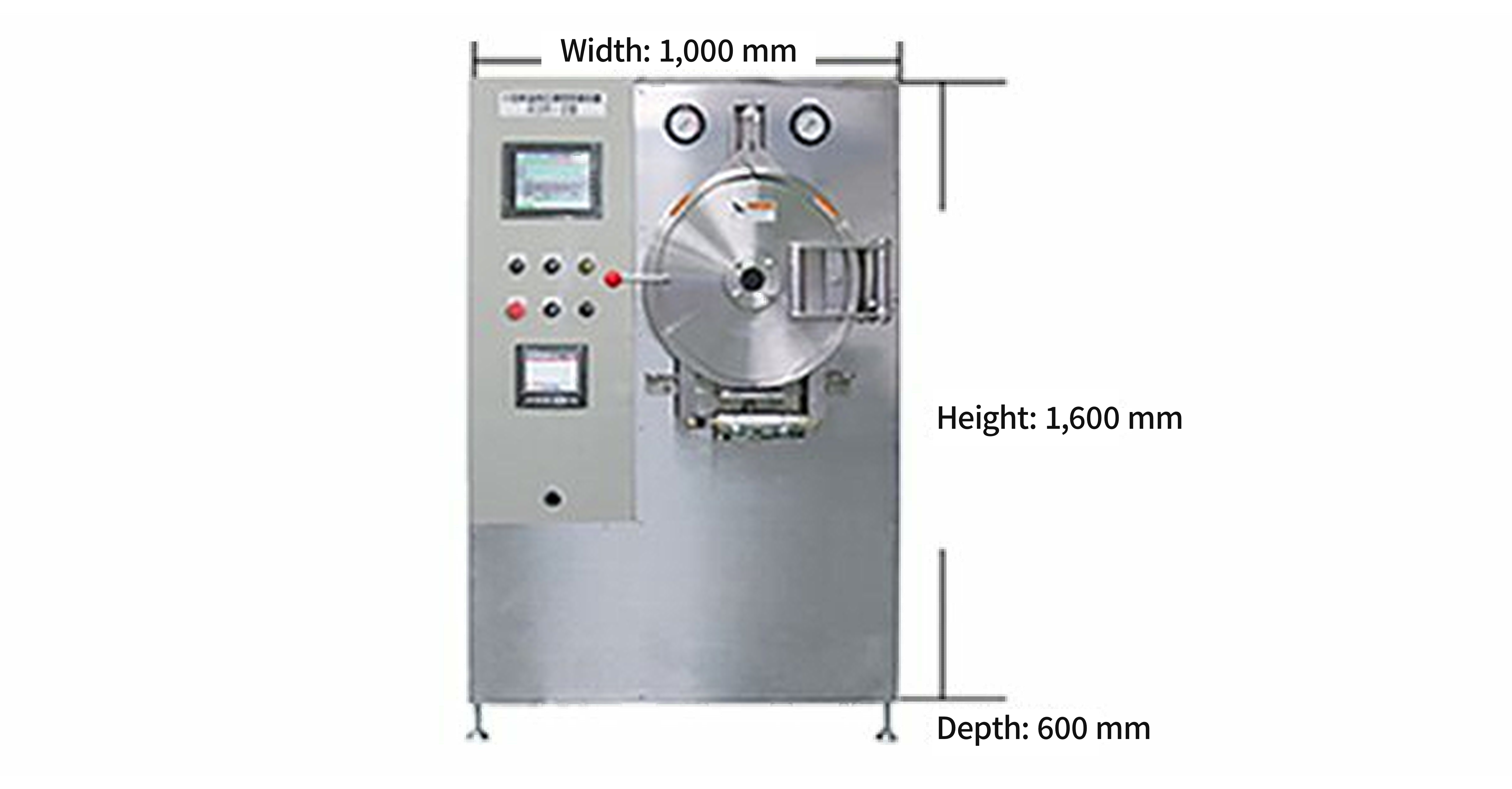

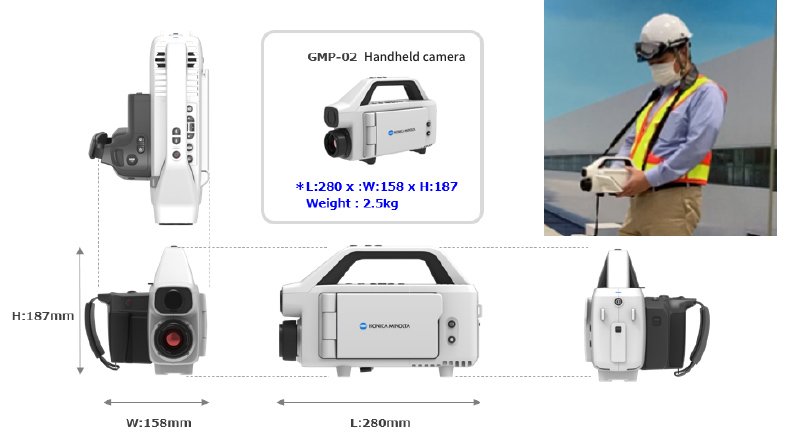

Specifications

| Product |

GMP02 handheld imaging system |

|---|---|

| Dimensions/weight |

281.5 × 155 × 186 mm, approx. 2.5 kg (including battery) |

| Continuous battery life |

Approx. 2 hr. (with new battery; battery is replaceable) |

| Operating temperature |

-20-50 °C (ambient temperature) |

| Angle of view |

Horizontal: 40°, vertical: 32° |

|

Detection time |

Within 3 sec. (typ. 1 sec.) |

| Detected gases |

Methane, ethane, propane, pentane, hexane, heptane, octane, ethylene, isoprene, 1-pentene, benzene, toluene, xylene, ethylbenzene, propylene, methanol, ethanol, formaldehyde, acetaldehyde, acetone, methyl ethyl ketone, methyl isobutyl ketone, other ethers, esters, and other hydrocarbon gases except acetylene |

| Detection sensitivity |

10 % LEL・m (for methane) |

| Protection rating |

Non-explosionproof; dustproof and waterproof (IP54) |

Examples of undetectable gases: ammonia, carbon monoxide, hydrogen, hydrogen sulfide. More information is available online or from our distributors.

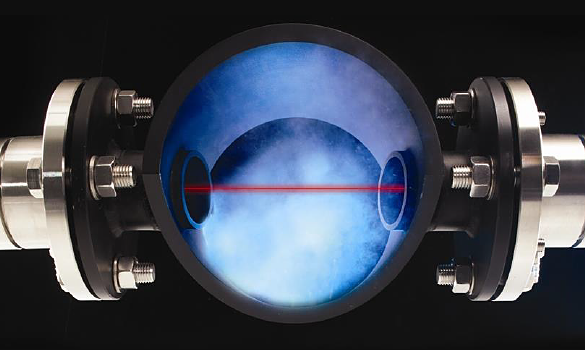

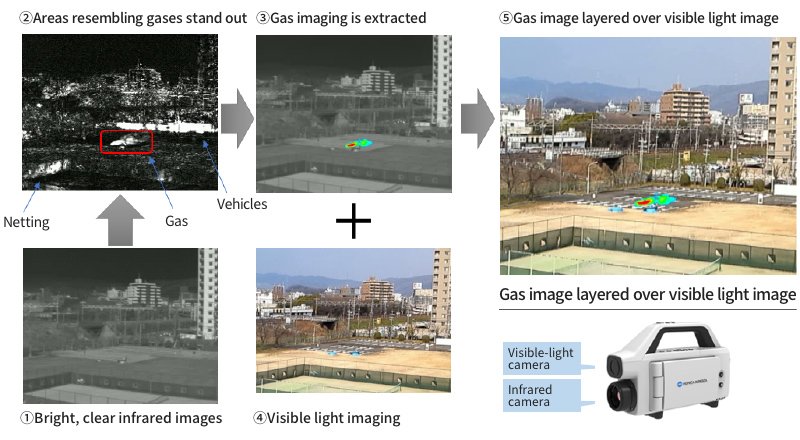

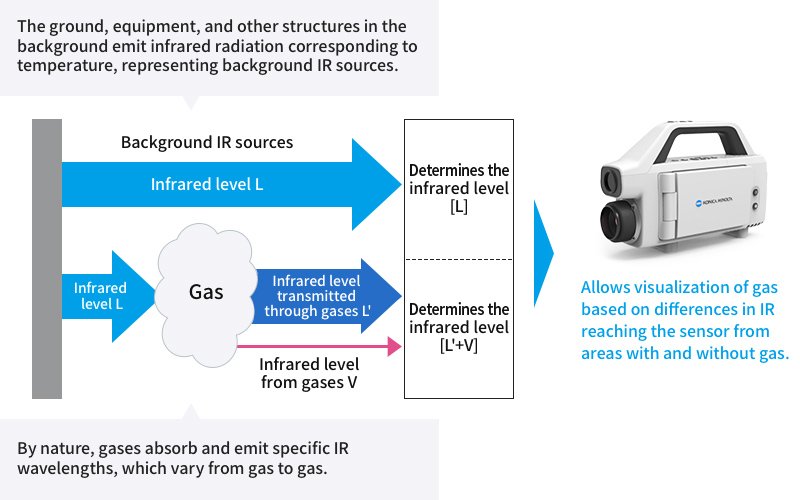

Principle

Applications

-

- More efficient routine inspections

-

Several inspection areas can be checked at once to quickly identify any leaks.

-

- Disaster assessment

-

In the event of an emergency, gas imaging helps ensure safety for responders.

-

- Inspections following regular maintenance

-

Following confirmation of airtightness, suitable for final inspections when pressurizing equipment for production

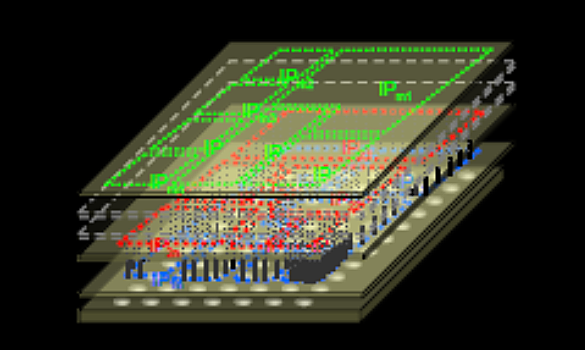

Structural Diagram

Industry's Smallest and Lightest* Facilitating Inspection

As a compact unit with a built-in battery, it can be readily carried anywhere for immediate use. Streamlines both routine inspection and initial assessment after disasters.

Can be handheld or mounted on a tripod.

*As of November, 2021.

Quickly Locate Leaks on the Monitor

Invisible gases are visualized on the camera monitor, making it easy to find leaks. Leaks can be located even more reliably by switching imaging modes to suit conditions such as weather, time of day, or site.

*Visualization graphics are overlaid on the camera feed.

Convenient User Interface

An easy-to-hold grip and buttons shaped and arranged with field operation in mind make switching screens or recording easy, even with gloves on.

Competitive Comparison

Enables intuitive leak identification, with gas image areas from IR imaging layered over visible light imaging.

For product inquiries, please submit the contact form.