Chemical-free polymer removal

HYPOX was developed by Italy-based MOVEngineering for removal of polymers adhering to various mechanical parts. Nearly 400 units have been sold around the world. Safe and easy to operate, the cleaning system applies hydrolysis, pyrolysis, and resin oxidation to remove solidified polymers stuck on nozzles, filters, gear pumps, extruder screws, and molds used in film or fiber production as well as substances such as carbon residuals, oligomers, and gels that are difficult to remove conventionally. No solvents or chemical substances are used in this automated, unattended process, which does not damage products. Not only is the system effective in removing oligomers and gels, it’s especially useful in cleaning delicate parts such as sintered metal filters, which are not damaged in the process. Capable of relatively low-temperature cleaning, HYPOX does not weaken common heat-sensitive metal base materials or surface finishes.

Highlights

- An indoor system enabling safe removal of stuck-on polymers while keeping the environment clean

- Does not carbonize polymers

- No solid or fume emissions

Although a minimal amount of wastewater containing broken down polymers is generated, this can be eliminated as an option. - Chemical-free process that relies solely on steam, air pressure, electricity, and water

- Lower running costs than conventional methods

- Fully automatic, with no manual tasks after loading

- Can be added to production lines

No need to remove and clean filters from any filter units included

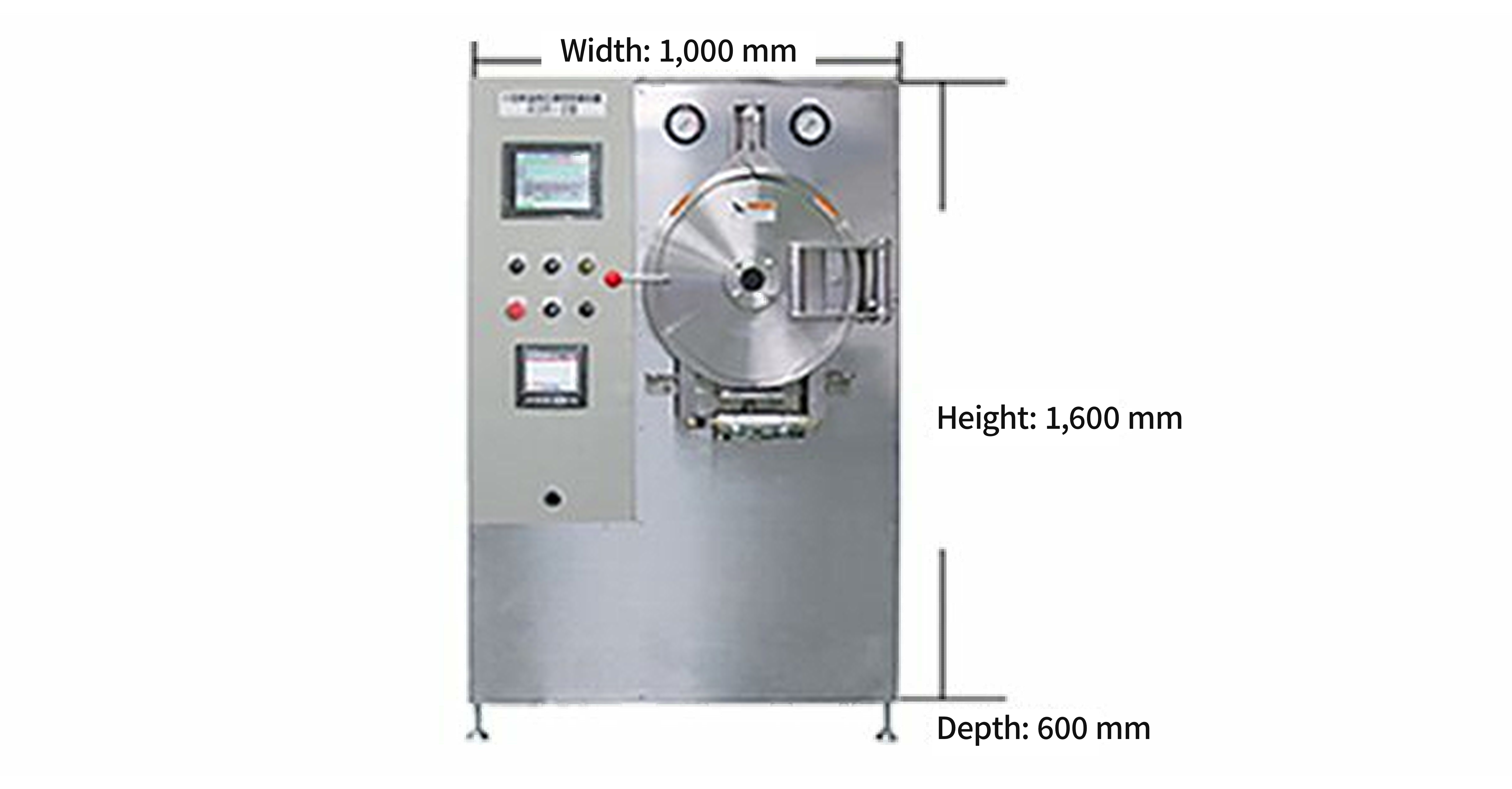

Specifications

Cleaning Process

① Hydrolysis: Anaerobic removal of polymers, gels, and oligomers with steam at about 400 °C

② Oxidation: Removal of carbon residuals with heated air at over 400 °C

These two processes are combined to remove polymers stuck on parts in an automated sequence that normally takes 8–15 hours.

Polymers Targeted

Proven to be effective for PET, PA6, PA66, PC, PP, PE, PBT, PU, ABS, COP, COC, cellulose, and other polymers

*Can be tested for cleaning of other polymers

Testing Facility

A testing facility is being established in Iwakuni, Yamaguchi.

| Examples of cleaning applications | |

|---|---|

|

Models are available to clean objects ranging from smaller than a meter to several meters. *All are ideal for gentle cleaning. |

|

|

1 |

Spin packs and related parts, spinnerets, spinning nozzles |

|

2 |

Gear pumps, molds |

|

3 |

Filter housing assemblies, sintered metal filters |

|

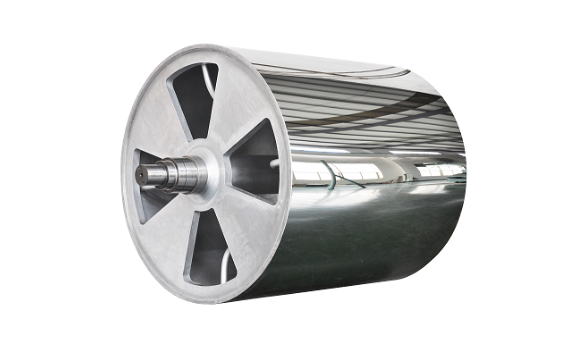

4 |

Dies for film or nonwoven fabric |

|

5 |

Extruder screws, heads, breaker plates |

|

6 |

Heat exchangers, static mixers |

For product inquiries, please submit the contact form.