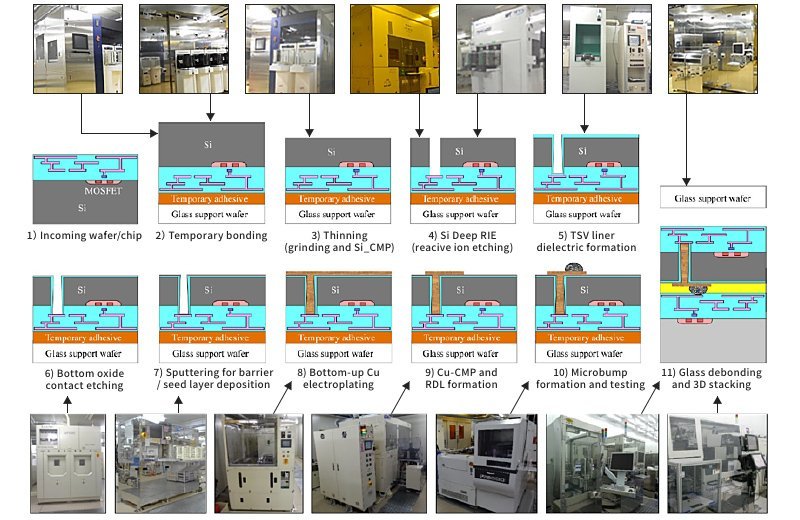

Supporting next-gen package development, up to 2.xD and 3D

Semiconductor Contract Processing

Seika assists customers with development and prototyping at one of the country's leading 12-inch production lines. The services we provide range from Test Element Group (TEG) fabrications to Si interposer, Through Silicon Vias (TSV) formation, deposition, RIE, microbump formation, and MEMS processing.

Applying 3D IC manufacturing technologies, we respond flexibly to processing needs of all kinds. Whether customers require small-lot or various processing, Seika provides one-stop service for single to complex processes using technology and equipment for TSV formation.

Contract processing services applying 3D and FOWLP technology make Seika a valuable ally for customers developing advanced packaging.

Highlights

- Integrated support from wafer thinning and TSV formation to rewiring, chip-to-chip bump formation, bonding, and gap filling

- R&D and prototyping support through 3D stacking of IC chips

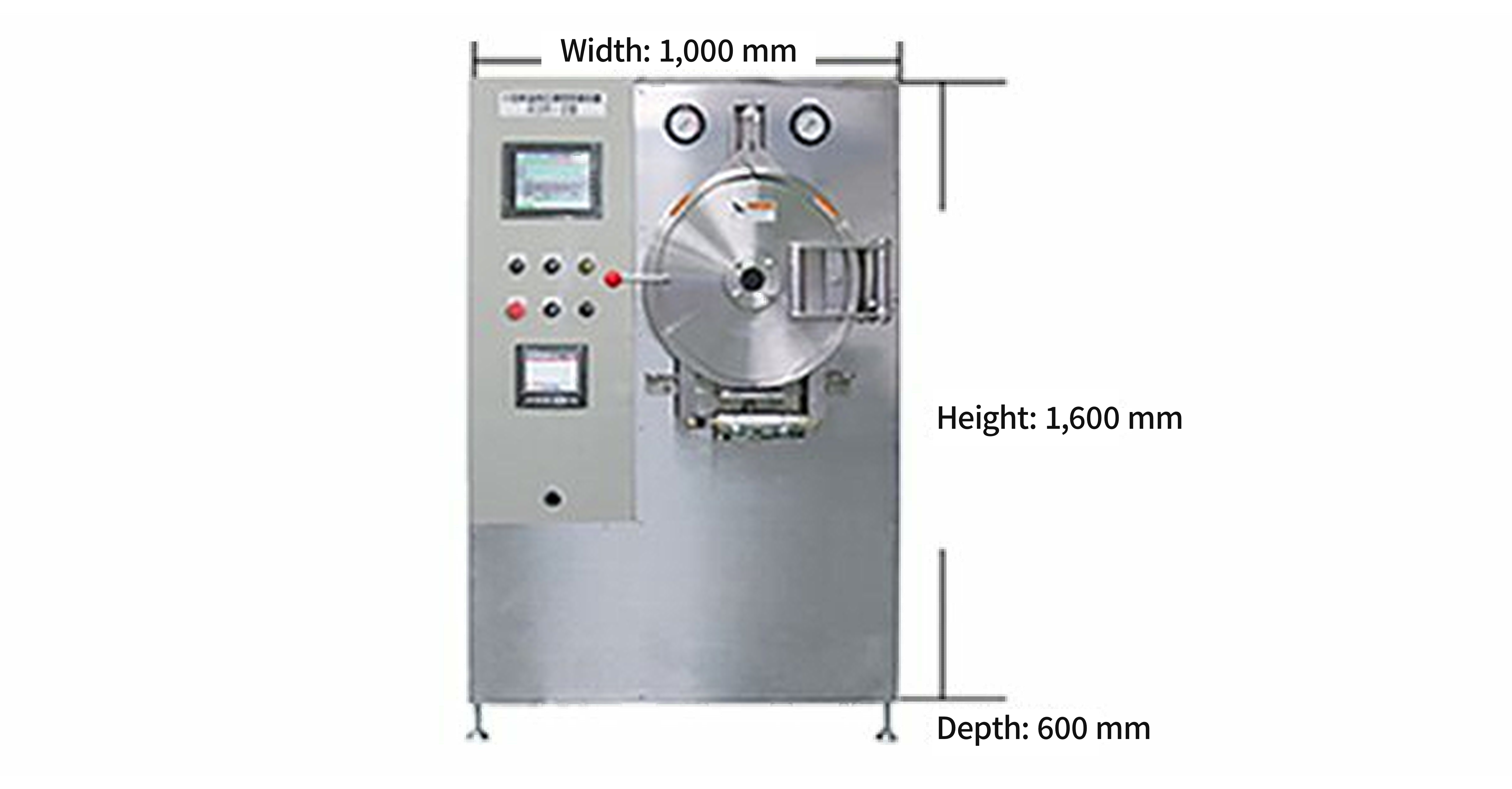

- Prototyping and sample provision for 3D LSI devices using 2, 8, or 12-inch wafers

- Prototyping and small-volume production of silicon interposers using 12-inch wafers

- Fabrication of other structures using LSI and MEMS processes

Seika-Owned Equipment Used in All Production Processes

Examples of Contract Processing Inquiries

- Companies struggling to perform prototyping at their own facilities and considering outsourcing

- Companies who already outsource but have difficulty managing individual processes outsourced to several suppliers

- Companies requiring TEG wafer fabrication to develop basic 3D bonding technologies (hybrid or bump bonding)

- Companies developing 3D IC materials or equipment

Companies prototyping TEG wafers for testing or evaluation - Companies testing under various conditions

- Companies for whom minimum order quantities are a barrier that prevents progress toward goals

For product inquiries, please submit the contact form.