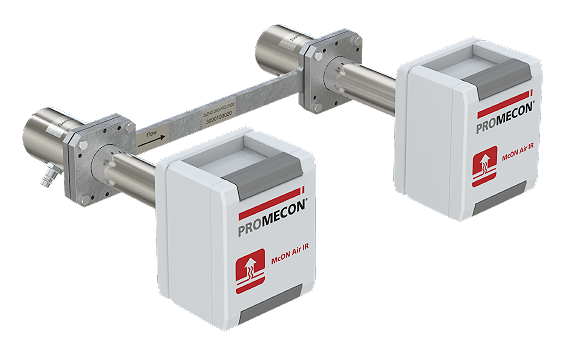

TDLAS analyzers with leading market share worldwide

Laser Gas Analyzers

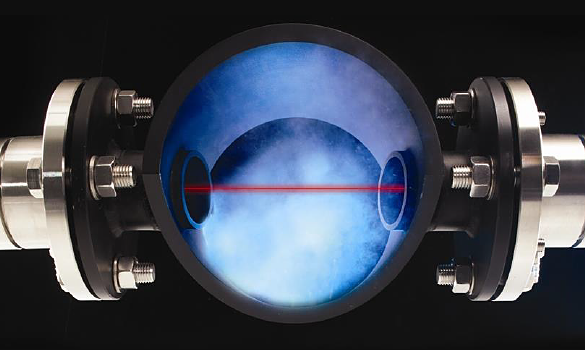

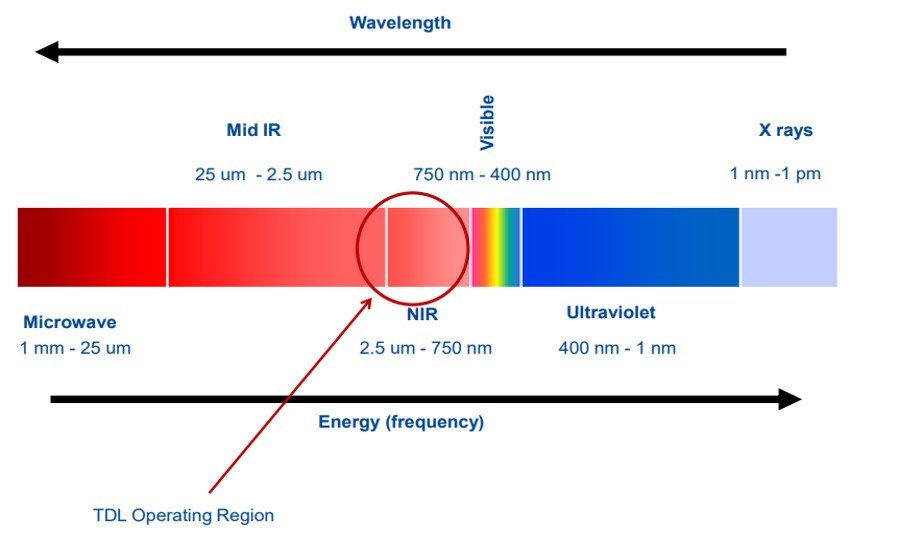

Laser gas analyzers are tools that use lasers diodes to analyze gas absorption, with TDLAS representing tunable diode laser absorption spectroscopy.

The analyzers work on the principle that irradiating exhaust gas, chimneys, or the like with a near-infrared laser tuned to a specific wavelength causes the laser to be absorbed by certain molecules. Applying this principle lets users detect and monitor oxygen, carbon dioxide, methane, ammonia, hydrogen chloride, and other gases. Direct gas measurement without sampling also provides a means of non-contact measurement without any special preparation such as changing the temperature. This also enables measurement of dihydrogen, which was difficult using conventional technology.

Highlights

- Essentially maintenance-free; only O-rings need replacement

Products sold in 1998 are still in operation. - No zero/span drift, in principle

- Responsive: measures within 2 sec.

Enables early detection if tolerance is exceeded, and prompt process control and safety management. - Site-specific flange connections and sampling methods can be proposed

- No special preparation required—direct measurement of raw gas, even under harsh conditions

Can be used in environments with high temperatures, dust, saturation, mist, or corrosive/toxic gas. - Accurate measurement without interference by coexisting gases

Offers advantages from the standpoint of lower limit, accuracy, and the range of gases that can be measured. - Models available that meet domestic explosion proof guidelines

Specifications

| Specifications |

Max. meas. length (pipe inner diameter):20 m Response time :Approx. 2 sec. or less Span drift :Not exceeding 4 % of measurable range Zero drift :Not exceeding 2 % of measurable range |

|---|---|

| Environmental conditions |

Ambient temp. :-20 °C to 55 °C (optionally up to 65 °C) Storage temp. :-20 °C to 55 °C Protection rating:IP66 |

| Inputs/outputs |

Analog output :4–20 mA (concentration/transmittance) Digital output (optional) :TCP/IP, Modbus, fiber optic Relay output :Alarm relay (minor failure), error relay (major failure) Analog input :4–20 mA (temp./pressure output available) |

| Power specifications |

Power supply :100 VAC, 50/60 Hz Power consumption :Max. 20 W 4–20 mA output :Max. 500 Ohms (isolated) Relay output :1 A at 30 VDC/AC

|

| Laser class |

Laser class:Class 1 CE :Certified EMC :2014/30/EU compliant |

|

Explosion-proof compliance |

Domestic explosion-proof guidelines (zone 1, 2):Ex in nA nC IIC T4/T5 Gc, Ex tc IIIC T100 °C Dc |

| Installation |

Flange diameter:ANSI 2 in./150 lbs. (equivalent to JIS 10K 50A) Other diameters available on request (parallel within 1.5°)

Purging :N2 or air purging Purge flow :30–100 l/min. (depending on gas conditions)

|

| Maintenance |

Annual calibration recommended |

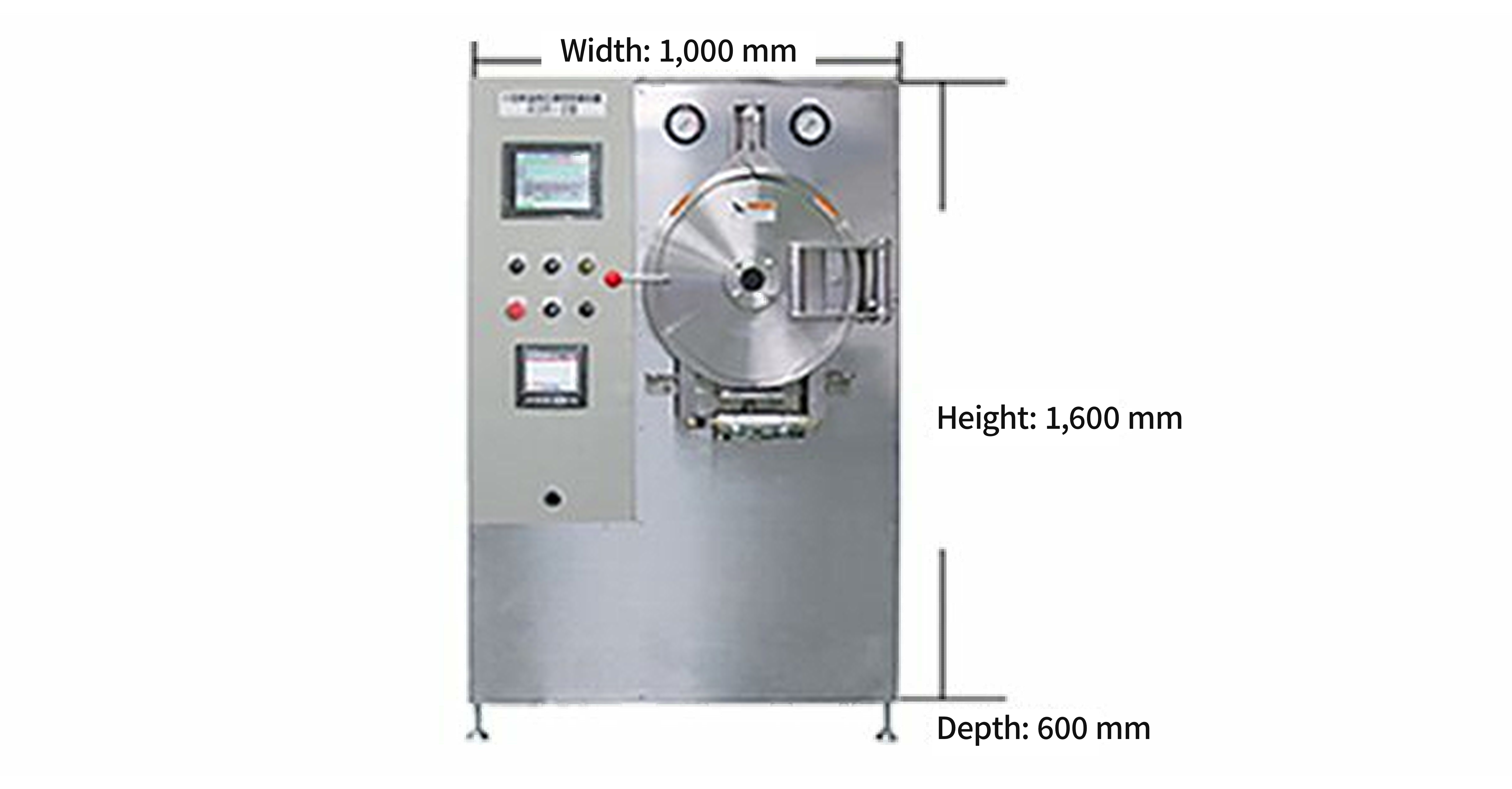

| Dimensions/weight |

Transmitter :428 × 266 × 166 mm, 7 kg Transmitter (explosion-proof) :405 × 270 × 310 mm, 8 kg Receiving unit :355 × 125 × 125 mm, 3.9 kg |

Principle

The analyzers employ near-infrared single-line absorption spectroscopy using a diode laser as a light source.

Each molecule has its own frequency, which causes laser light of the same frequency to resonate with the molecule, and in turn, absorb (attenuate) the light energy.

Applications

Combustion improvement:

Measurement of high-temperature gases (O2, CO, etc.) at the outlet of incinerators for heating, melting, or combustion furnaces, etc.

Quality control:

Measurement of impurities or by-products in process gases on production lines (NH3, H2O, HCL, etc.)

Air pollution monitoring:

Measurement of low concentrations in biomass exhaust gas (NH3, HCL, HF, CO2, etc.)

Explosion prevention:

Constant monitoring (of O2, CO, etc.) to prevent explosion

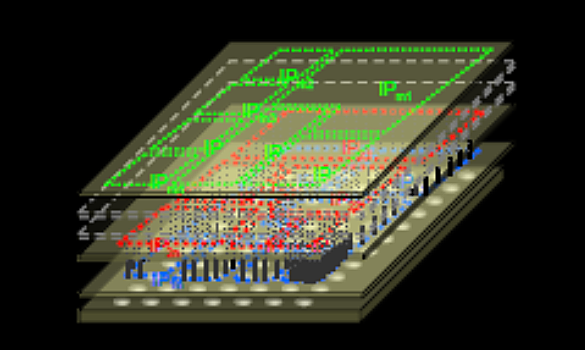

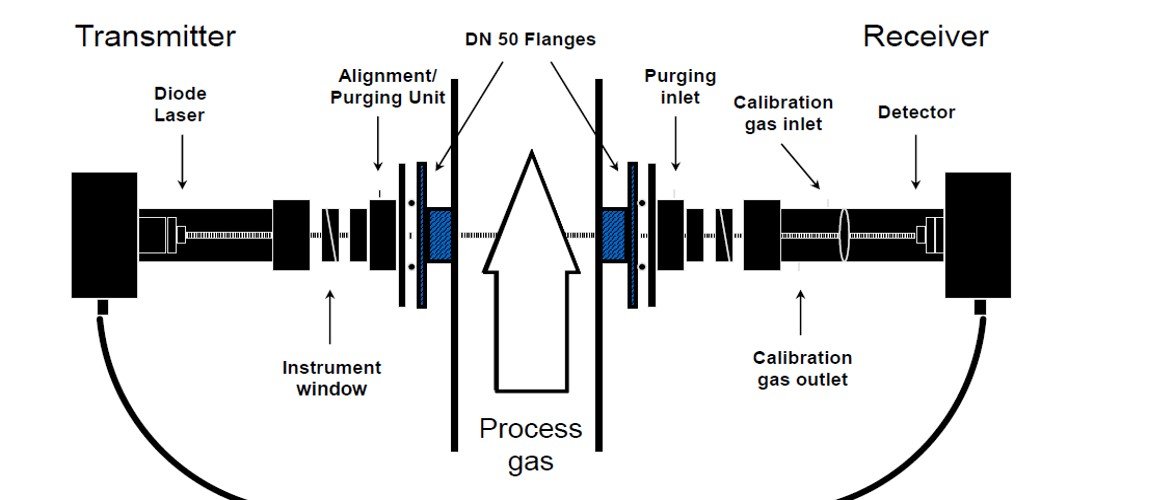

Structural Diagram

As instruments that measure gas concentration, these products essentially consist of a light transmitter incorporating a diode laser and a receiver incorporating a photodetector. Both parts feature air purging and optical axis alignment functions. The transmitter incorporates an LCD screen that shows measured gas concentration, laser transmittance, and any error messages in the event of malfunction.

For product inquiries, please submit the contact form.