A form of decarbonization that requires no capital investment

Natural Pellets: Torrefied Biomass Fuel

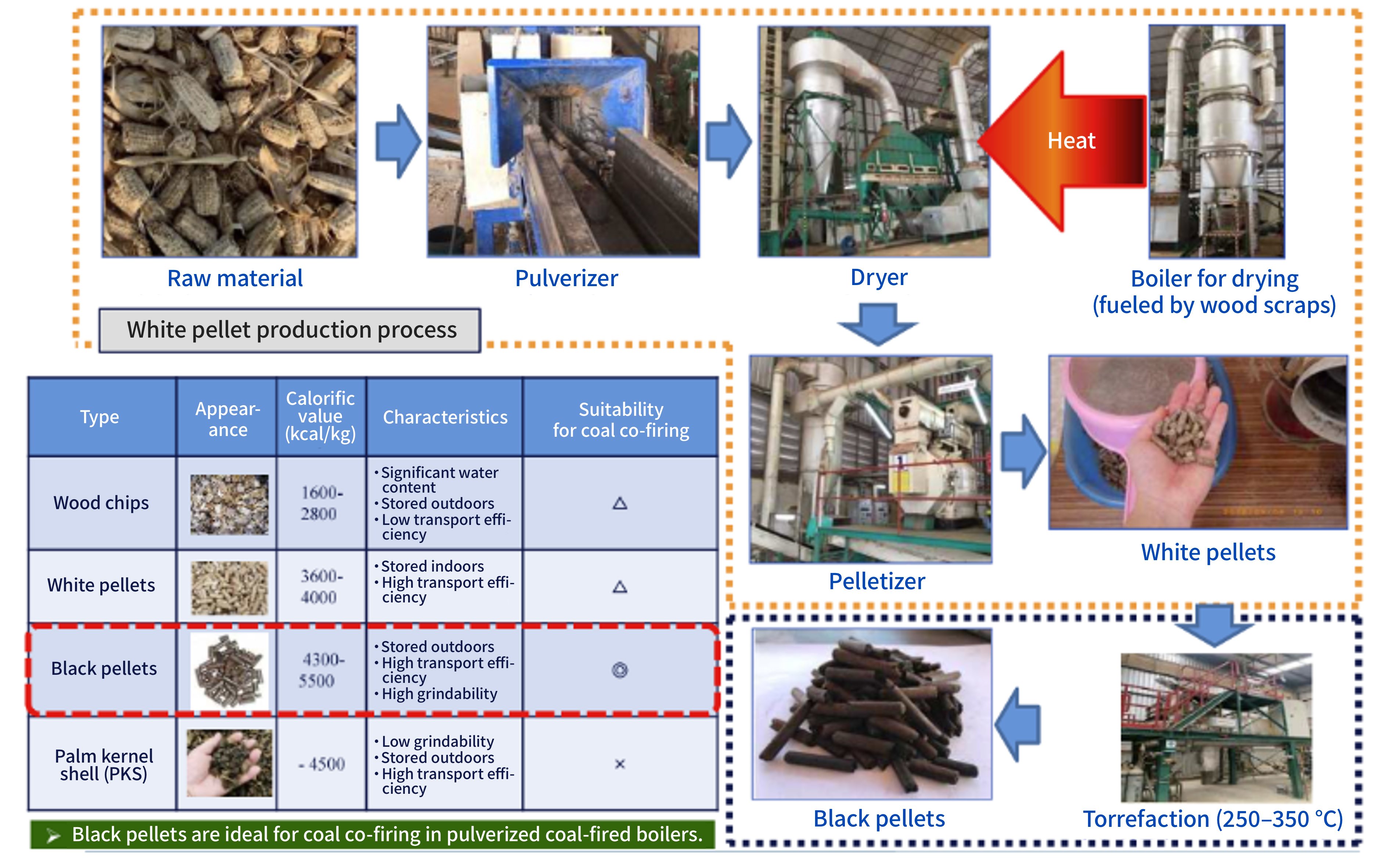

Natural pellets are semi-carbonized (torrefied) biomass fuel with improved properties, portability, quality, and safety than wood chips or white pellets. Developed as an alternative to coal or coke, natural pellets support decarbonization without requiring modification of existing coal/coke facilities such as pulverized coal-fired boilers, blast furnaces, or electric furnaces.

Natural pellets are prepared using the FlashTor process devised by Blackwood Technology, a veteran in European biomass fuel supply. Built in Thailand by leading Thai EPC contractor TTCL, this plant has an annual supply capacity of 75,000 tons.

Although plants or crop residues of all kinds can be used to make natural pellets to suit client needs, the Thai plant is designed to support effective use of residues from corn. This also addresses the environmental issue of farmers otherwise burning corn residues, which generates large volumes of particulate matter (PM 2.5).

Highlights

- Decarbonization without the need to modify existing coal/coke facilities

- A fuel with favorable properties, portability, quality, and safety capable of serving as a substitute for coal/coke

- Enables the use of corn residue and various other raw materials.

- Applies FlashTor torrefaction developed by Blackwood, with years of experience in supplying Europe with biomass.

- Plant construction was managed by TTCL, a leading Thai EPC contractor.

-

Annual supply capacity: 75,000 tons

Specifications

| Property | Unit | Quality | ||

|---|---|---|---|---|

|

Thermal coal substitute (for power generation) |

Coking coal substitute (for iron/steel) |

|||

| Diameter |

mm |

As received |

6–8 |

6–8 |

| Length |

mm |

As received |

3.15 < L < 40 |

3.15 < L < 40 |

| Bulk density |

kg/m3 |

As received |

≥ 510 |

360–500 |

|

Mechanical durability |

wt% |

As received |

≥ 95 |

70–95 |

|

Total moisture |

wt% |

As received |

≤ 10 |

≤ 10 |

|

Gross calorific value |

kcal/kg MJ/kg |

Dry basis |

Average 5,000 Average 21 |

5,000–6,800 21–28.5 |

*AR: As received basis, DB: Dry basis; These values are only for reference. Actual quality varies depending on the raw material.

Reasons to Use Natural Pellets

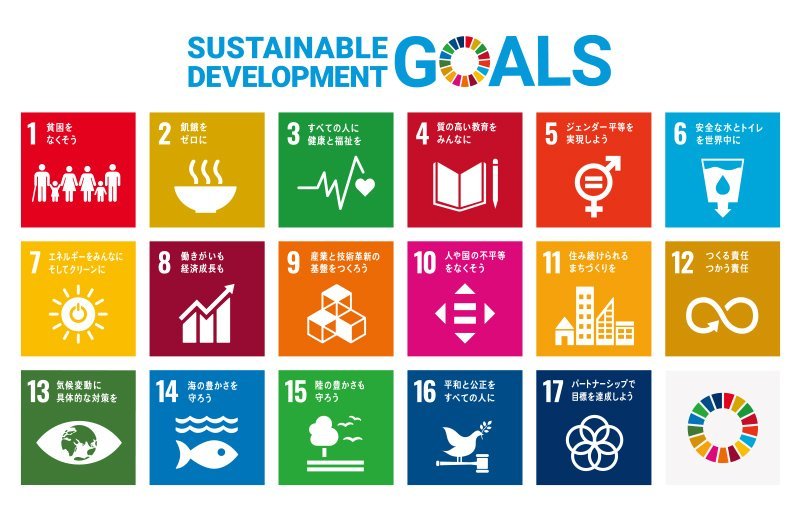

Natural pellets are made from crop residue (especially corn residue) to prevent the open burning—a serious source of air pollution in Thailand—and reduce PM 2.5. Natural pellets respond to 12 of the sustainable development goals.

12 SDGs Addressed Through Seika Business

■ Goals 1 and 2: No Poverty, Zero Hunger

Farmers can earn money selling crop residue otherwise discarded as waste. The additional income helps improve farmers' quality of life, including a better diet and nutrition.

■ Goal 3: Good Health and Well-Being

Natural pellets are made from crop residue that would otherwise be burned in fields by farmers, becoming a primary source of PM 2.5 emissions. By reducing PM 2.5 emissions, this project helps the people of Thailand live healthier, better lives.

■ Goal 5: Gender Equality

Seika plants provide equal opportunities to all members regardless of gender, from engineers and equipment operators to administrative staff and security guards.

■ Goal 7: Affordable and Clean Energy

Natural pellets can be produced using FlashTor torrefaction from a wide variety of raw materials around the world. This will make renewable energy more accessible.

■ Goal 8: Decent Work and Economic Growth

These efforts promote economic growth in the form of returns to investors, additional income for farmers, and creation of local job opportunities and tax revenue.

■ Goal 9: Industry, Innovation, and Infrastructure

The project has introduced innovative FlashTor technology from the Netherlands.

■ Goal 11: Sustainable Cities and Communities

In addition to providing a sustainable fuel source and reducing local environmental impacts, the project helps improve Thai air quality by reducing PM 2.5 that would otherwise be generated by farmers burning crop residue.

■ Goal 12: Responsible Consumption and Production

Turning crop residue into fuel reduces the amount of waste generated.

■ Goal 13: Climate Action

As an alternative to fossil fuels, natural pellets support carbon neutrality.

■ Goal 16: Peace, Justice, and Strong Institutions

Seika ensures regulatory compliance in pursuing economic interests and fulfilling social obligations.

■ Goal 17: Partnerships for the Goals

Responding to various SDGs requires cooperation between local governments and residents, private companies and public institutions, and national and regional governments.

Principle

Applications

-

- Pulverized coal-fired boilers

-

Pellets are used in place of coal

-

- Blast furnaces

-

Pellets are used in place of PCI and coke

-

- Electric furnaces

-

Pellets are used in place of coke

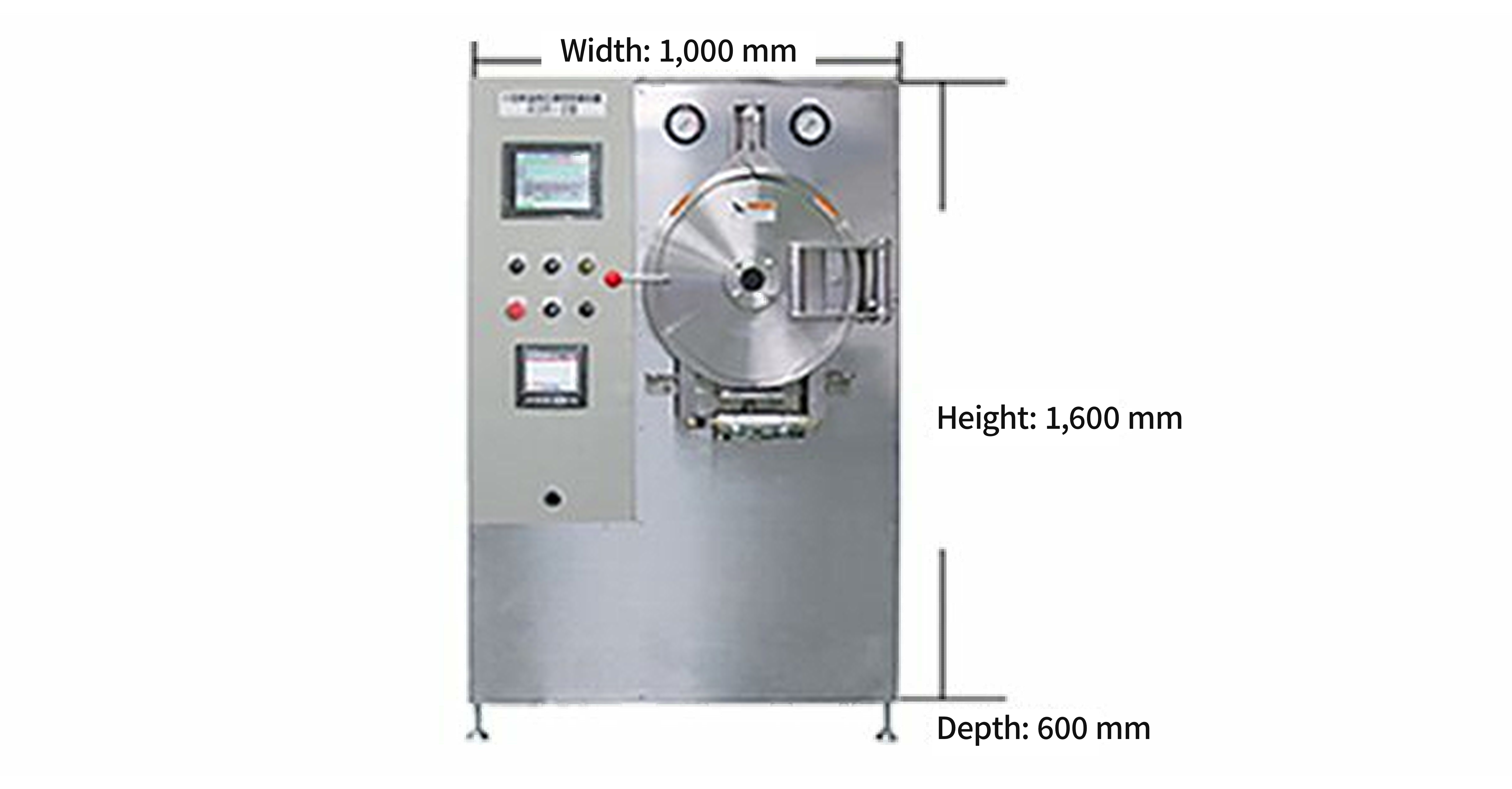

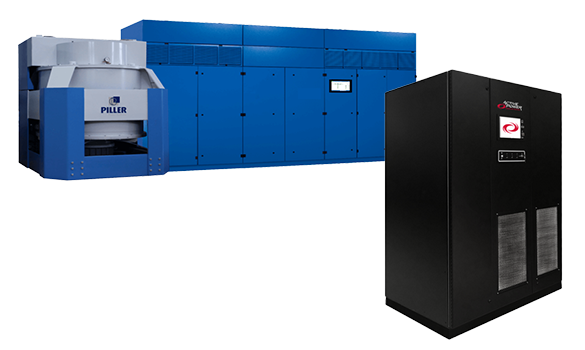

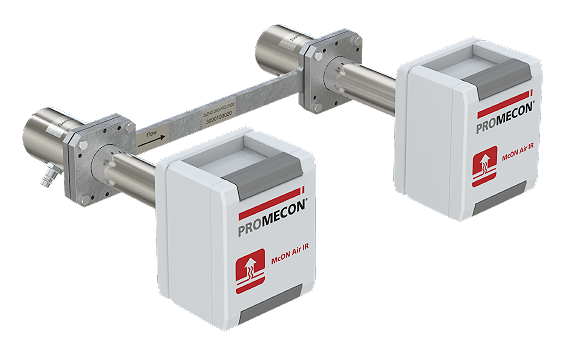

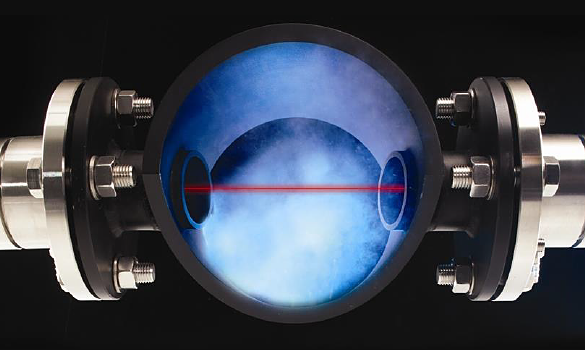

System Elements

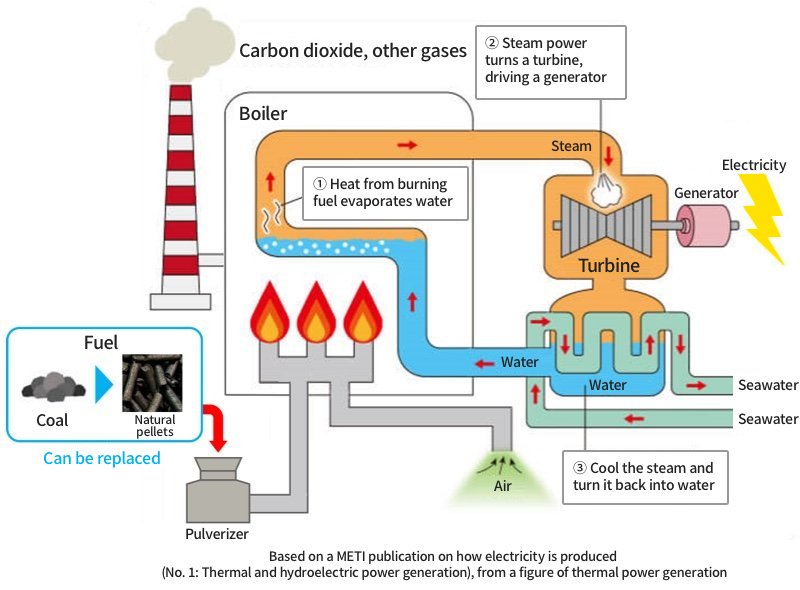

Use in Pulverized Coal-Fired Boilers

Without modifying pulverizers or combustion systems, natural pellets are a biomass fuel that can be used in place of coal.

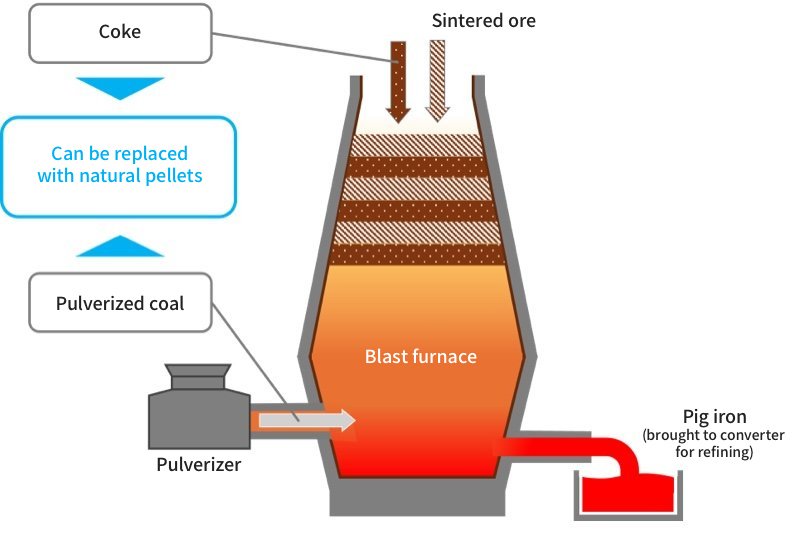

Use in Steelmaking

Without modifying blast or electric furnaces, natural pellets can be used in place of coke or pulverized coal as a reducing agent to remove oxygen from iron ore.

For product inquiries, please submit the contact form.