No batteries required—rotation produces clean sinusoidal output and ensures a stable supply of green power.

Flywheel UPS Systems

Flywheel uninterruptible power supply (UPS) systems provide power for a certain period after momentary or extended outages of the electrical grid. Instead of relying on rechargeable batteries such as lead-acid or lithium-ion batteries, it employs a flywheel system that converts electrical energy into kinetic energy and stores it. They are widely deployed where power failure or voltage drops have a great impact—such as at data centers and production sites like semiconductor foundries—to enhance power supply reliability, availability, and security across many fields. Combining these systems with emergency generators enables a longer-lasting .

With no need for batteries, flywheel UPS systems also save space. Free of harmful chemicals, they represent a sustainable, environmentally-friendly solution that also offers long service life.

Highlights

-

- Highly reliable

-

Unlike battery-based systems, no fixed lifespan or loss of capacity

-

- Exceptionally efficient

-

Maintains high efficiency of up to 98 % as a parallel online unit constantly compensating for electrical grid fluctuations.

-

- Scalable

-

High scalability—modular product line

-

- Protects from momentary to extended failures.

-

Recharges in less than 3 minutes, which also helps reduce emergency generator running time.

-

- Compact

-

Smaller and lighter than battery systems

-

- Proven performance

-

Extensive installation record worldwide

-

- Long service life

-

Proven operation beyond 20 years with annual inspections and bearing replacement every few years

-

- Sustainable

-

Contains no hazardous substances; made with recyclable materials.

-

- Easy maintenance

-

Eliminates need for frequent maintenance such as of battery systems, thereby reducing operating costs.

-

- Safe

-

Low fire risk; eliminates need for special safety measures.

-

- Broad range of operating temperatures

-

No loss of performance in operating temperatures of 0–40 °C, reducing electricity and air conditioning costs

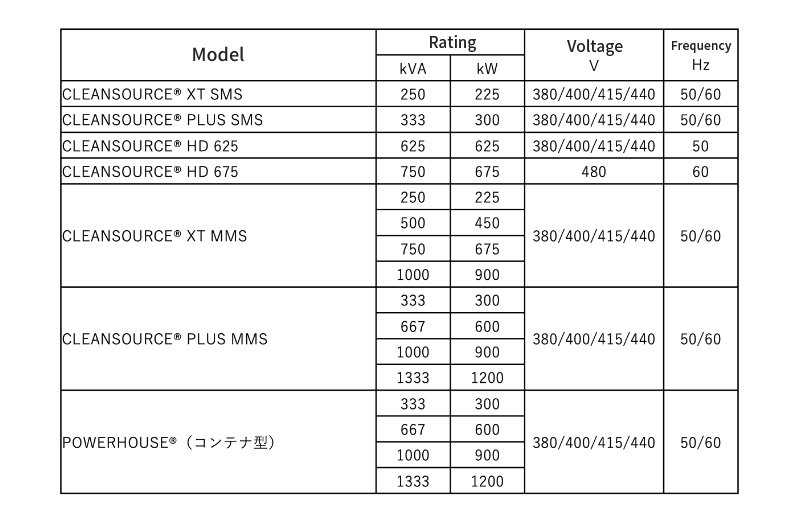

Product Line

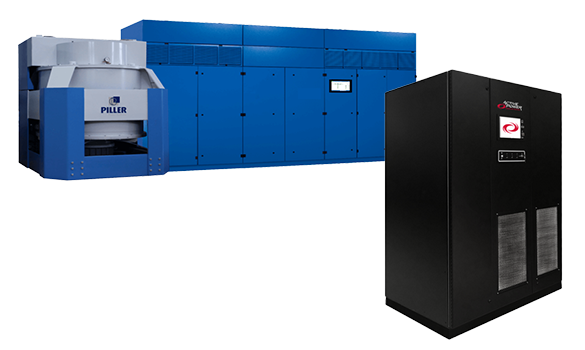

Piller Low/High Voltage UPS

- High-voltage: Configurable up to 34 kV (50/60 Hz)

- Low-voltage: 400/690 V (50 Hz), 480/600 V (60 Hz)

- Up to 98 % efficiency in space-saving units

- Broad 0–40 °C range of operating temperatures

- Long 20+ year product life

Active Power CleanSource Plus SMS

- Single Module System

- 300 kW, 380/400/415/440 V @ 50/60 Hz

- Up to 98 % efficiency

- Half the space of battery systems

- Built-in maintenance bypass (optional)

- Broad 0–40 °C range of operating temperatures

- Long 20+ year product life

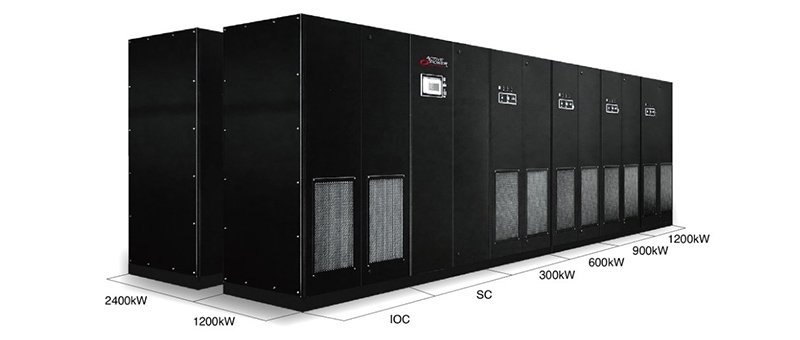

Active Power CleanSource Plus MMS

- Multi Module System

- 300–2,400 kW, 380/400/415/440 V @ 50/60 Hz (up to 300 kW × 8 units)

- Up to 98 % efficiency

- Half the space of battery systems

- Broad 0–40 °C range of operating temperatures

- Long 20+ year product life

Active Power CleanSource HD

- High Density

- 625 kW, 380/400/415/440 V @ 50 Hz

- 675 kW, 480 V @ 60 Hz

- Up to 98 % efficiency

- Combine modules to provide up to 5,400 kW (up to 8 units in parallel).

- Half the space of battery systems

- Broad 0–40 °C range of operating temperatures

- Long 20+ year product life

Active Power Powerhouse

- UPS in standard containers

- Compatible with operating temperatures between -25 °C to 50 °C

- Highly durable

- Factory-built, factory-tested plug & play system

- Standard container size for easy transport

-

-

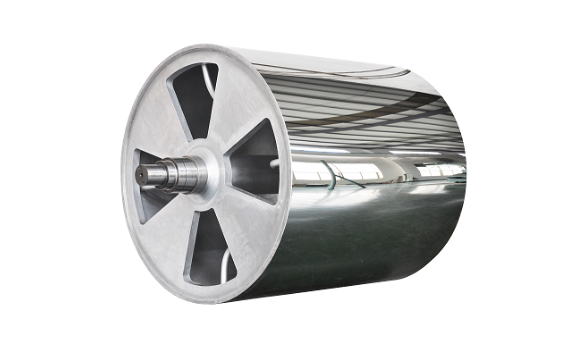

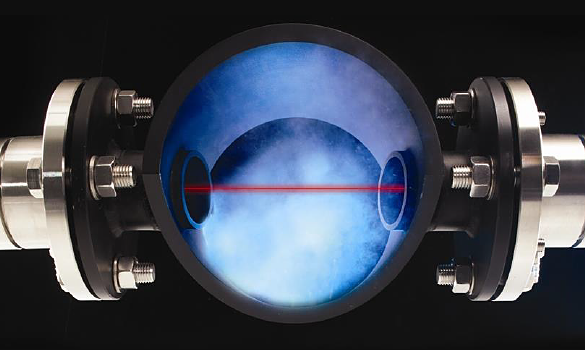

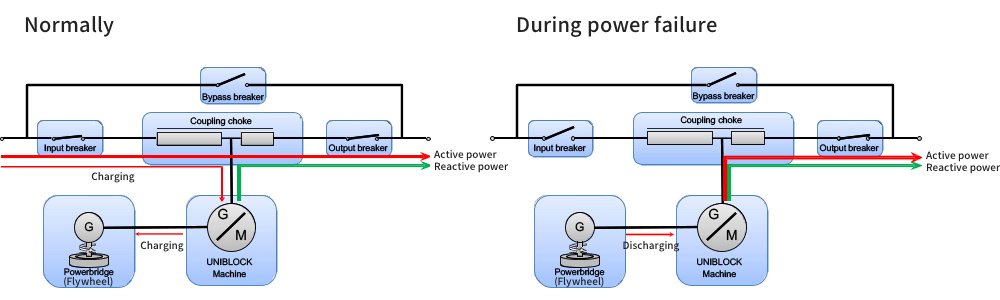

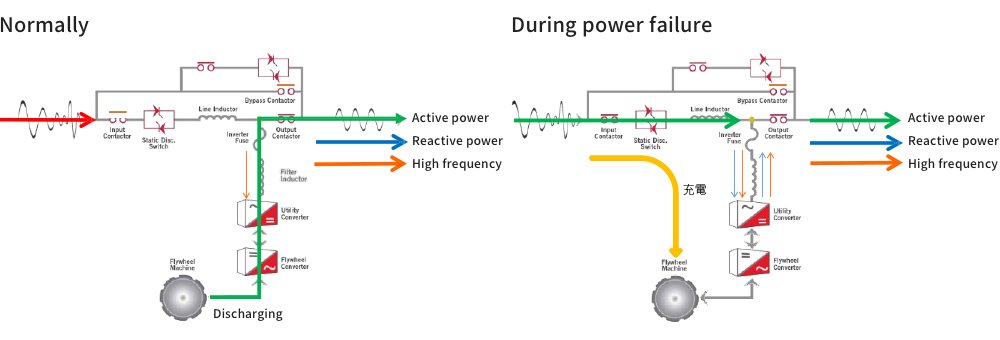

Principle

The UPS system, at normal times, serves as an electric motor to control the flywheel to spin at its rated speed in a low-friction vacuum housing. Magnetic control reduces the weight borne by the lower part of the bearing, allowing efficient rotation by the heavy rotor to store kinetic energy with minimal power consumption.

During outages or under similar conditions, the system switches roles, serving as a generator to supply backup power for emergency load by converting the kinetic energy of the rotor (which continues spinning due to inertia) into electrical energy.

Applications

These flywheel UPS systems protect emergency load against all nine IEEE power disturbances: power failures, sags, surges (spikes), undervoltage, overvoltage, line noise, frequency variations, switching transients, and harmonic distortion. When used in combination with a generator, the systems operate for the time required to switch to generator power in the event of an emergency, ensuring stable, uninterrupted operation. In recent years, these systems have also been used to stabilize industrial microgrids and renewable energy sources.

Examples: Data centers, healthcare and pharmaceutical industries, telecommunications/broadcasting, manufacturing, semiconductor industry, logistics, aviation, finance, leisure/casino facilities, microgrids

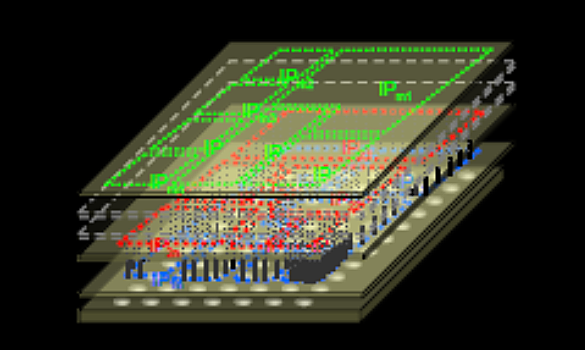

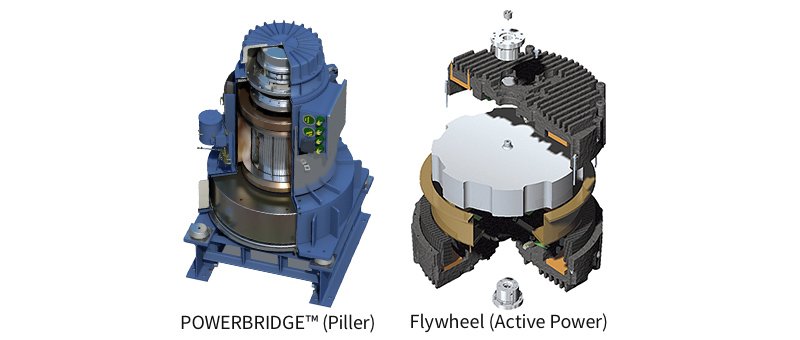

Structural Diagram

Piller Power

Piller Power System Elements

-

-

Active Power

Active Power System Elements

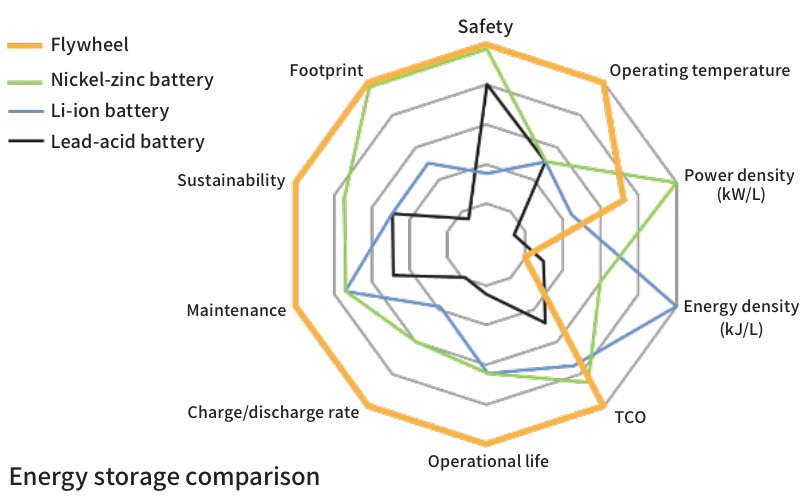

Competitive Comparison

Energy Storage

With the many options available for UPS energy storage, versatility is a key differentiator. Each application has its own requirements for how long a system must cover for outages; the solutions must be tailored to these needs. While energy-dense options are appealing for longer periods, power density is the key factor when rapid bursts of energy are needed for a minute or less.

Unlike conventional energy-dense alternatives, flywheel UPS systems stand out for unmatched sustainability, longevity, safety, compact size, and TCO.

Flywheels have earned a reputation for their outstanding reliability. They’re simpler than battery systems, with fewer parts prone to failure. This reliability allows flywheels to continue supplying power to critical equipment during outages.

Maintenance is minimal, reducing long-term operating costs. With flywheels, it is easy to visualize operating conditions, which adds to stable performance. These systems last longer than battery systems, allowing use over many years. They are also environmentally-friendly products—free of hazardous chemicals and concerns about ultimate disposal. They’re highly efficient and can reduce energy consumption.

These advantages set apart flywheel technology as a reliable, sustainable option for UPS systems that can effectively meet mission-critical power needs across many fields.

Power Supply

The parallel online architecture of flywheel UPS systems places the inverter and charger circuitry or transformer in parallel with the AC power supply. With this design, the power consumed is supplied directly from the grid while the UPS system's capacitors and electronic controls compensate for over- or under-voltages in the incoming power to eliminate transients, voltage fluctuations, and other disturbances.

In other constant inverter power supply (double conversion) UPS systems, all power is rectified from AC to DC and inverted from DC to AC, ensuring a perfect sine wave and frequency protection on the output. However, this approach requires significant energy for inversion. In cases involving low load factors, the efficiency losses tend to be especially noticeable. Recent years have seen developments such as eco mode, which promises higher efficiency by relying on electrical grid power most of the time, but because power conditioning is completely abandoned, it may lead to long-term damage of protected loads.

The flywheel UPS system also controls frequency fluctuation (kept as low as ±0.2 %) to provide compensation equivalent to that of a constant inverter power supply, but in a simpler, more energy-efficient design.

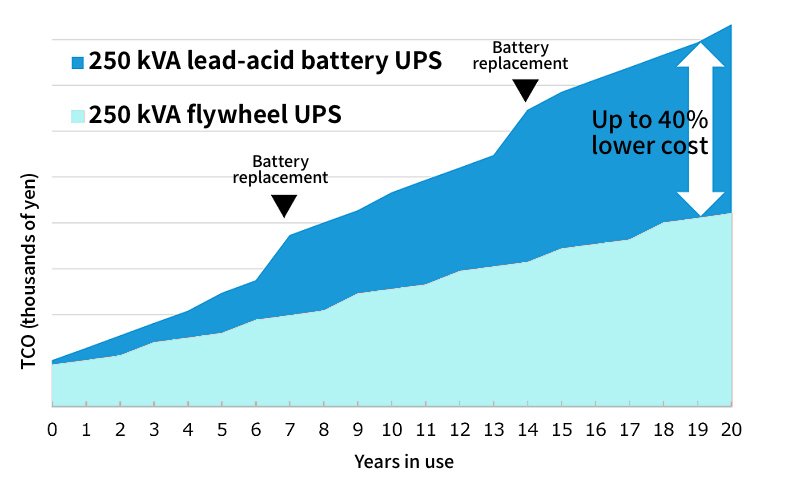

Operating Costs

The parallel online architecture of flywheel UPS systems configures the inverter and charger circuitry or transformer in parallel with the AC power supply. With this design, the power consumed is supplied directly from the grid while the UPS system's capacitors and electronic control compensate for over- or under-voltages in the incoming power and eliminate transients, voltage fluctuations, and other disturbances.

In other constant inverter power supply (double conversion) UPS systems, all power is rectified from AC to DC and inverted from DC to AC, ensuring a perfect sine wave and frequency protection on the output. However, this approach uses a significant amount of energy for inversion. In cases involving low load factors, the efficiency losses tend to be especially noticeable. Recent years have seen developments such as eco mode, which promise higher efficiency by relying on electrical grid power most of the time, but because power conditioning is completely abandoned, it may lead to long-term damage of protected loads.

The flywheel UPS system also controls frequency fluctuation (kept as low as ±0.2 %) to provide compensation equivalent to that of a constant inverter power supply, but in a simpler, more energy-efficient design.

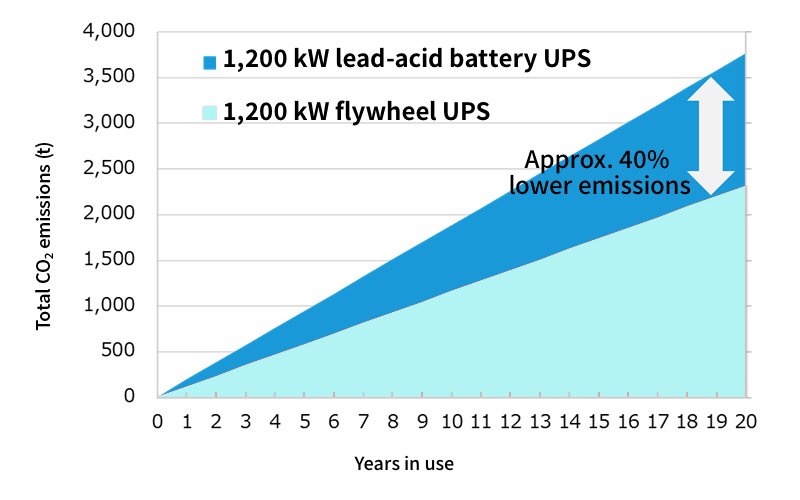

Sustainable

The high energy efficiency and less stringent cooling requirements of flywheel UPS systems can reduce their carbon footprint when in use. They also require up to 90 % less carbon to manufacture the necessary parts than lead-acid batteries.

And in contrast to the nearly 100 % steel content of the flywheel itself (the most recyclable material), lead-acid and lithium-ion batteries must be carefully disposed of and pose various environmental impact and pollution risks.

Case Studies

White Papers

FAQ

What disturbances can the systems protect against?The systems can protect emergency loads against all nine IEEE power disturbances—power failure, sags, surges (spikes), undervoltage, overvoltage, line noise, frequency variations, switching transients, and harmonic distortion—allowing uninterrupted operation.

How long does the protection last during outages?Protection for about 15–60 seconds is generally targeted by flywheel UPS systems.

To allow us to suggest models that match your needs, please provide us with the following information.

∙ Voltage

∙ Frequency

∙ Preferred backup time

∙ Capacity (kVA and kW)

∙ Summary of load protectedCan the systems compensate for a series of sags or power failures?Yes. The systems can protect against multiple sags or power failures as long as the load is within capacity. Moreover, unlike rechargeable batteries, the systems store energy in the form of kinetic energy. This enables the system to quickly regain full charge. Even when flywheels are fully depleted, it takes less than three minutes to return to the specified spin speed.

Is any time required before switching to UPS backup power?After a power failure, there is no interruption of power when switching from the electrical grid to UPS backup power and back, after service from the grid resumes (within the time the UPS is designed to provide backup power).

What backup capacity (in kVA/kW) is available?The minimum configuration provides 250 kVA (225 kW). Units of various capacities are available. Higher system capacities can be configured by choosing multiple identical units of the same capacity and connecting them in parallel. Redundant (n+1) configuration is also available.

Contact us for proposals that will meet your needs.What voltages are supported?Active Power UPS systems: 380, 400, 415, 420, 440, and 480 V. Piller Power UPS systems: 380, 400, 480, and 600 V. High voltage conforms to specifications (up to 34 kV).

Contact us if you are considering voltages other than these.What’s the range of operating temperatures?The operating temperature range is 0–40 °C (average daily temperature not exceeding 35 °C recommended).

What are the environmentally-friendly features?Key points allowing a small environmental footprint are as follows.

∙ High efficiency (up to 98 %)

∙ Lower power consumption, because air-conditioning is not needed or temperature control requirements are less stringent

∙ Easier to recycle, because it is classified as general industrial waste

∙ Battery-free, with no need to replace or dispose of batteriesHow are these systems different from products designed to protect against power sags?Most products that guard against sags only provide backup power for very brief voltage drops or power failures of a few seconds at most, and power to equipment stops for a few milliseconds before switching to backup power. UPS systems available from Seika not only provide backup power over a longer period after voltage drops or power failures but also provide constant protection from all IEEE power disturbances. Moreover, the power supply is not interrupted when switching to backup power.

How do these systems differ from emergency generators?After an electrical grid failure, the power supply will automatically switch to the UPS backup power to maintain power supply. (The duration for which the backup power will function depends on the UPS capacity.) In contrast, emergency generators can keep generating power as long as fuel is available. This enables longer backup, but power will not be available initially for up to one minute until the generator starts up after the power failure. Combining a UPS system with an emergency generator enables longer protection without an initial interruption of power to the load.

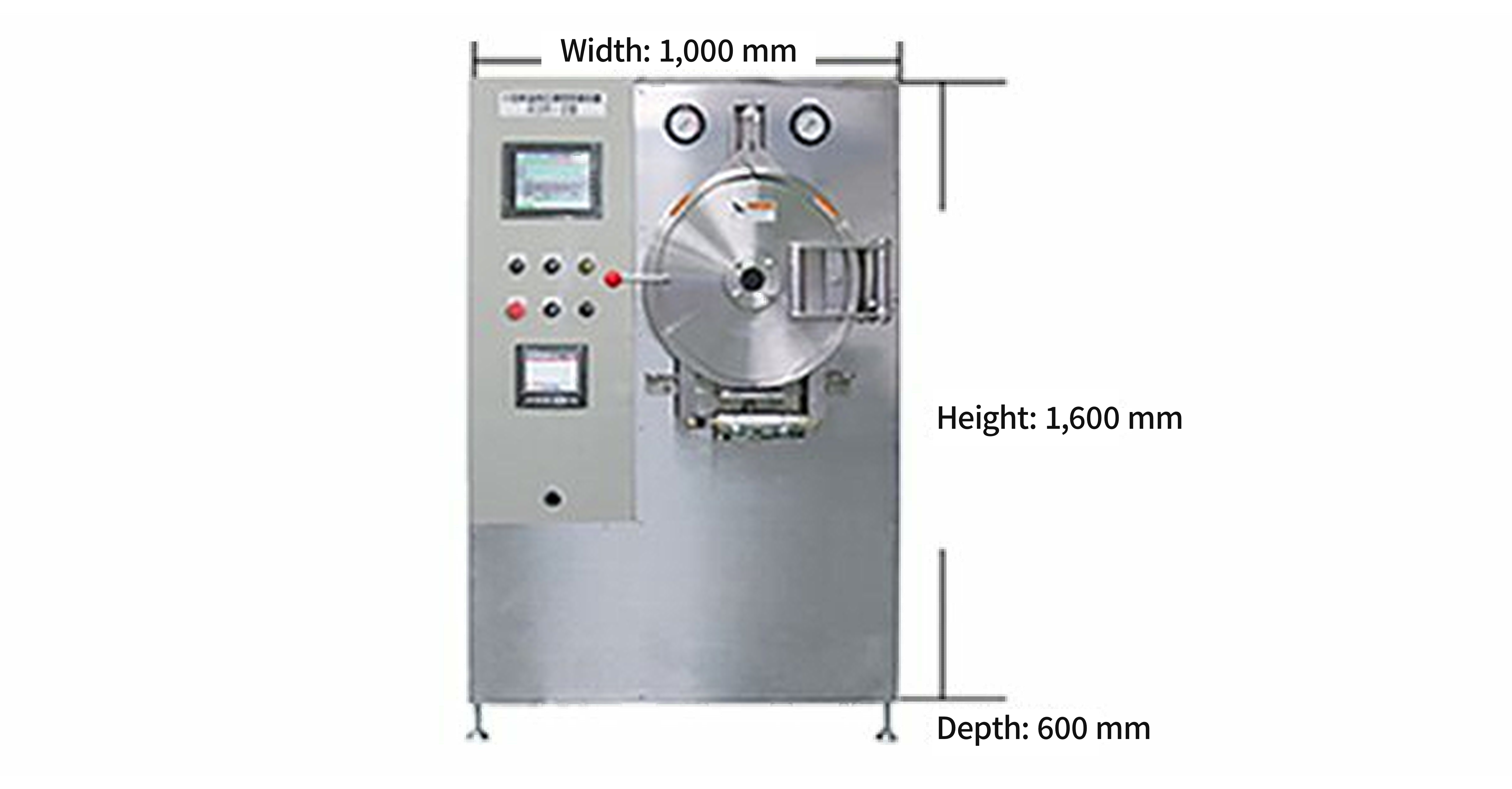

How large are the systems?Less space is required for installation compared to typical battery-powered UPS systems.

Example: A 333 kVA, 300kW@50 Hz system measures 3,226 × 865 × 1,981 (L×W×H, in mm)

Note that size varies according to product specifications. Contact us for more information.Can the systems be installed outdoors?The systems themselves are not waterproof and must be installed indoors. However, the compact design of the systems allows installation in a specialized shipping container, an option increasingly popular outside of Japan. This equipment is factory-installed and wired in the container, which cuts installation time and costs after delivery.

Do earthquakes pose specific risks for these systems?Seismic testing in Japan simulating earthquakes has confirmed that the systems are unaffected by earthquakes of up to 5 on the Japanese scale. Damping measures are also available.

Do rotary flywheel UPS systems generate significant noise?Reference values are as follows.

Active Power UPS audible noise: <75 dBA at 1 m

Piller Power UPS audible noise: <77 dBA at 1 mFlywheels spin at high speed. Isn’t that hazardous? Do they pose injury risks?Flywheels are enclosed in a robust housing to eliminate any risk of direct contact with users or flywheel escape.

The systems are manufactured outside of Japan. What maintenance arrangements are in place?Licensed engineers in Japan provide initial support should any issues arise.

Additionally, engineers at manufacturer offices in Asia provide remote support.

Remote monitoring and predictive diagnosis options are also available for certain products. Contact us for more information.Can maintenance be performed while the UPS system is online?Annual inspections can be performed while the system is online. Bearing replacement requires powering down the system. We recommend configuring systems with a maintenance bypass, which enables a continuous power supply from the electrical grid during maintenance.

Will we need to replace the flywheel during the useful life of the system?Unlike rechargeable batteries, flywheels do not lose capacity as they age. There is no need to replace the flywheels themselves. Note that the upper and lower flywheel bearings typically do require replacement.

How often should the bearings be replaced?We recommend relacing the bearings every 10 years for Piller Power UPS systems and every 3–4 years for Active Power UPS systems. Bearings are less costly than batteries to ensure lower operating costs than for battery-powered UPS systems.

What’s the product's useful life?The systems are designed to provide a useful life of 20 years. With appropriate maintenance, they can be used even longer.

Are demo units available?While no loaner units are available, systems are available for viewing at Seika offices. Interactive online viewing and inspection are also available. Contact us for more information.

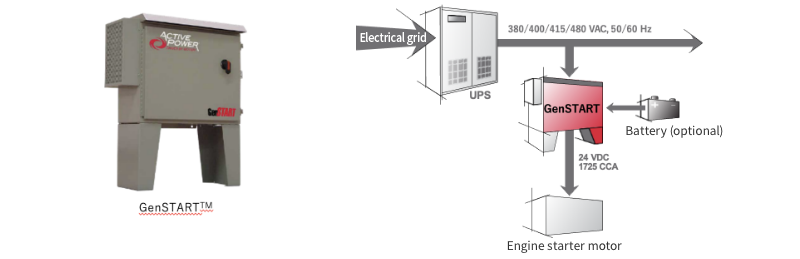

Related products: Active Power GenSTARTTM starting module for emergency generators

The GenSTARTTM from Active Power is a battery-free modular starting system that adds additional availability to emergency generators. While nearly all generators depend on batteries to provide cranking power, dead starting batteries still account for most emergency generator starting failures. GenSTARTTM is designed to enhance starting system reliability and ensure successful engine-cranking cycles.

-

For product inquiries, please submit the contact form.