Basic Policy

The Seika Group supports the sustainable generation of energy and industrial activities in harmony with the global environment as a corporate group centered on a trading company with strengths in the energy and industrial infrastructure fields.

Environmental Business Examples

In terms of the business of the VIORB 2030 long-term management vision, we set decarbonization, energy and resources conservation, circular economy, and DX as four priority domains, and we are constantly striving to expand and develop sales of “green innovation products” that contribute to the environment.

The following are the main initiatives currently undertaken by the Seika Group.

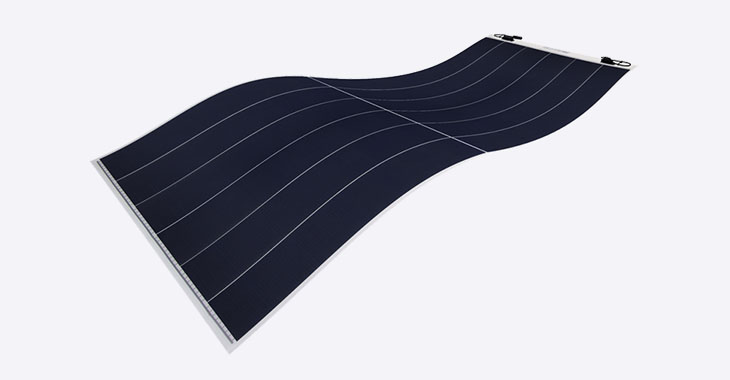

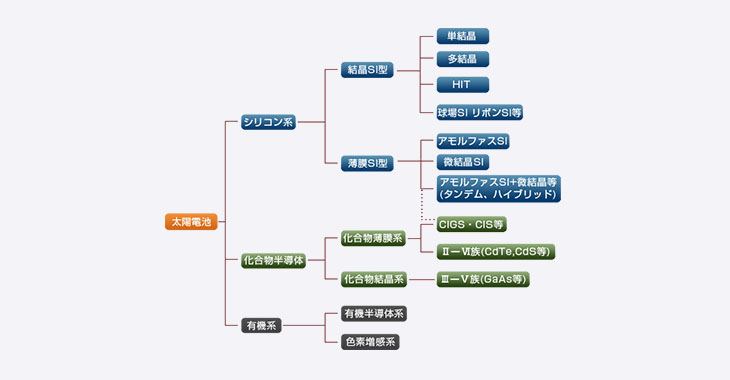

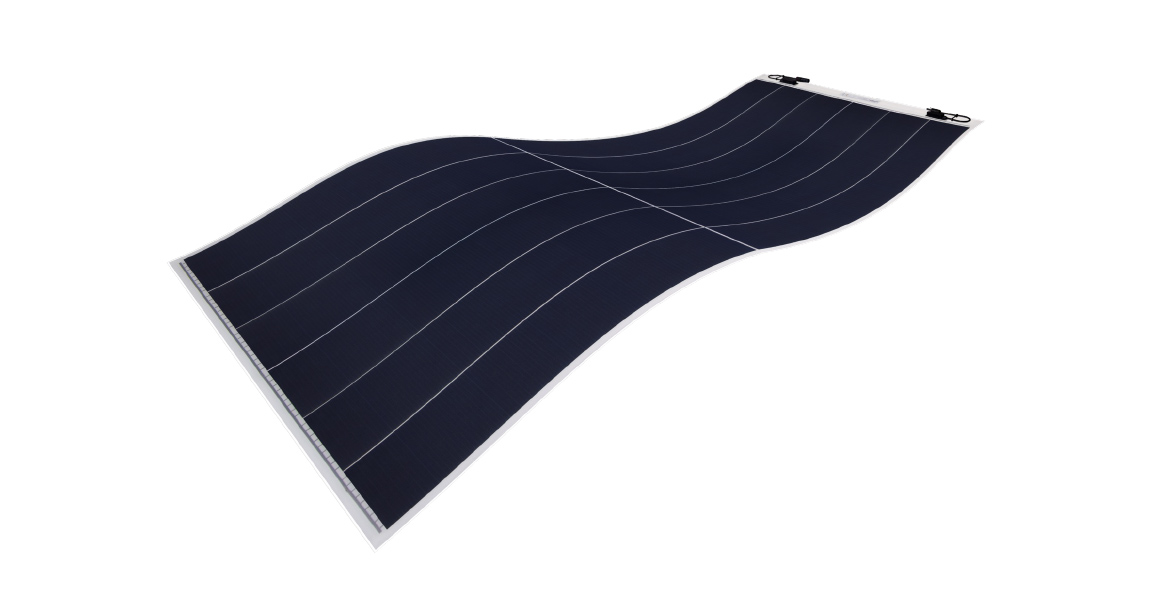

1. Sale of ultra-lightweight solar panels for renewable energy

Solar power generation is the method of generating power using solar cells to create electricity directly from the energy of the sun. Because it is a non-depletable natural energy source that does not produce GHG, it can contribute to the creation of a sustainable environment.

Since our ultra-lightweight solar panels achieve a high conversion efficiency and are half the weight or less of conventional solar panels, they can be considered for installation on flat roofs and low load-bearing roofs that traditionally cannot support conventional solar panels, and they are expected to have a full-fledged power generation effect.

In addition, our ultra-lightweight flexible solar panels (without a frame) can be adhered to a surface with double-sided tape or adhesive for improved workability and at significantly reduced installation costs, as mounting hardware and frames are not needed. Because the solar panels are flexible, they can be considered for installation on curved roofs and carports, and their light weight enables them to be effectively utilized on walls of buildings, plants, and warehouses. In snowy regions, in particular, the vertical installation on walls enables large power generation even when snowing.

In terms of the environment, while general solar panels commonly use lead, a hazardous substance, for the soldering of electrodes, our ultra-lightweight flexible solar panels use lead-free solder. Because lead-free soldering has a high melting point, cell breakage can occur due to thermal stress, and therefore, proper temperature and time control are required, and advanced technology is needed. The lead-free soldering of our solar panels and temperature adjustments are controlled automatically during manufacture, eliminating manual work to ensure stable product quality.

Related link: product introduction on Company’s website https://www.seika.com/product/solarpanel/

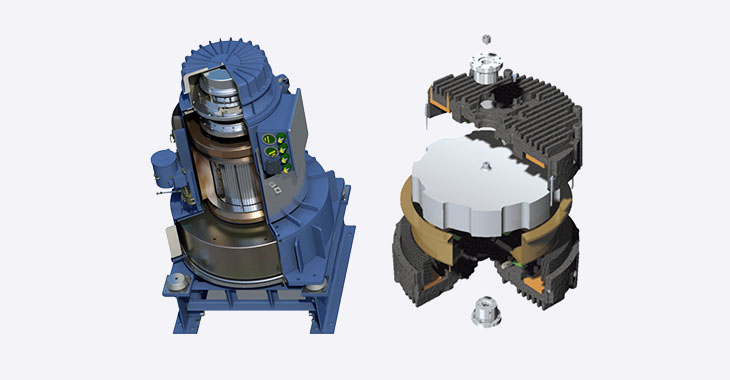

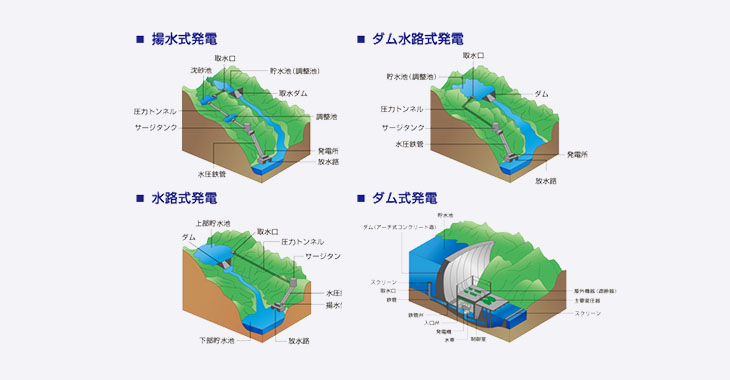

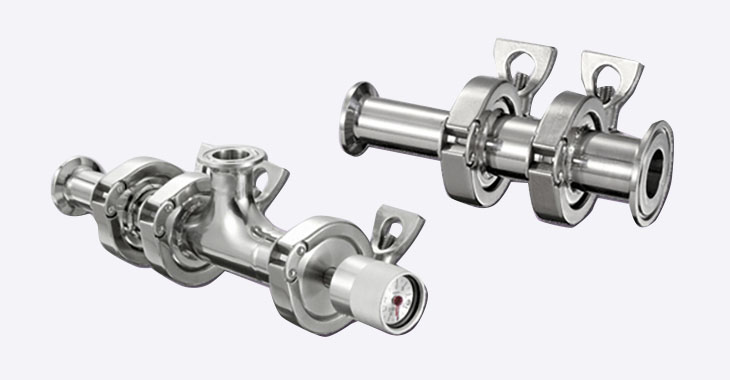

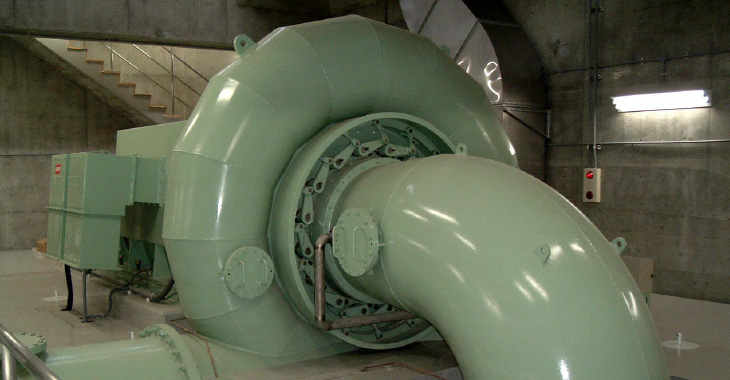

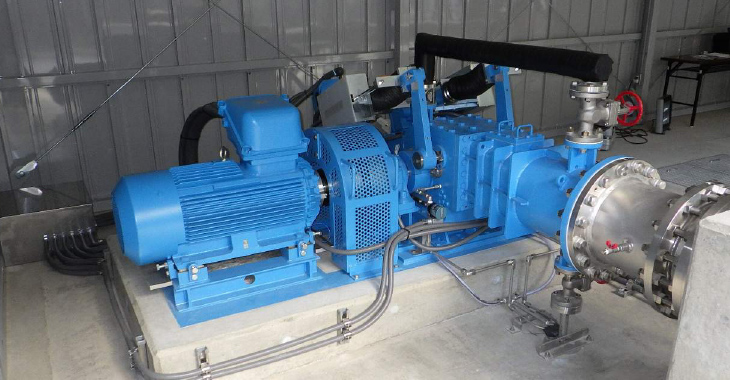

2. Delivery and maintenance of small-scale hydropower generation equipment

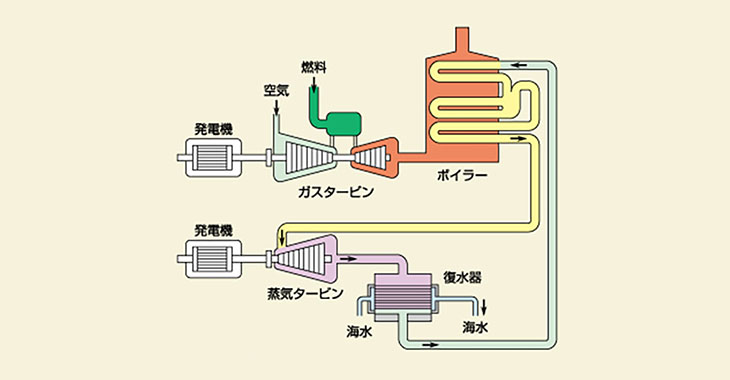

Hydropower generation involves dropping water stored at a high elevation to a low elevation, using the potential energy to rotate a turbine, which in turn rotates a generator connected to the turbine to generate electricity. Small-scale hydropower generation mainly uses a channel system (intake system), in which upstream water is fed to a turbine through a water pipe to generate energy, or a dam system (including regulating pond and reservoir systems), in which power is generated by dropping stored water using a dam. While we commonly think of large dams and rivers when it comes to hydropower generation, small-scale hydropower can use smaller agricultural channels, water supply facilities, and industrial water in addition to rivers and dams (including regulating pond, reservoir, and weir systems).

Hydropower generation creates clean, eco-friendly energy with numerous benefits that include the following:

- Pure domestic energy

- Renewable energy

- Energy that does not produce GHG

In addition, compared to other power generation facilities,

hydropower facilities have a longer lifetime, thereby maximizing the use of limited resources.

While small-scale hydropower generation has the same basic configuration as hydropower generation, the power output is small and the equipment is also on a smaller scale.

- Because the water flow rate is low, there is very little river water pollution and impact on aquatic life.

- Small-scale hydropower is easy to install with less deformation of the terrain for short construction time.

- Maintenance can be performed easily with a short suspension of operations for a high equipment utilization rate.

These benefits help minimize the impact on the surrounding natural environment and enable efficient power generation.

The construction of a power generation plant involves many factors including location, drop (difference in elevation), and flow rate. For example, the flow rate is affected by the weather (rain and snow) and continues to fluctuate throughout the year, and if a dam is installed, its water level may also fluctuate. To maximize the amount of power generation under these various conditions, Seika Corporation provides optimal equipment for various hydropower generation types throughout Japan for both new construction and renewal of existing facilities. In addition to turbines, we also supply inlet valves, power generators, control panels, and other equipment required for power generation facilities. We continue to promote clean energy by providing technology that supports small-scale hydropower generation to ensure a stable power supply.

Related link: product introduction on Company’s website https://www.seika.com/product/water/

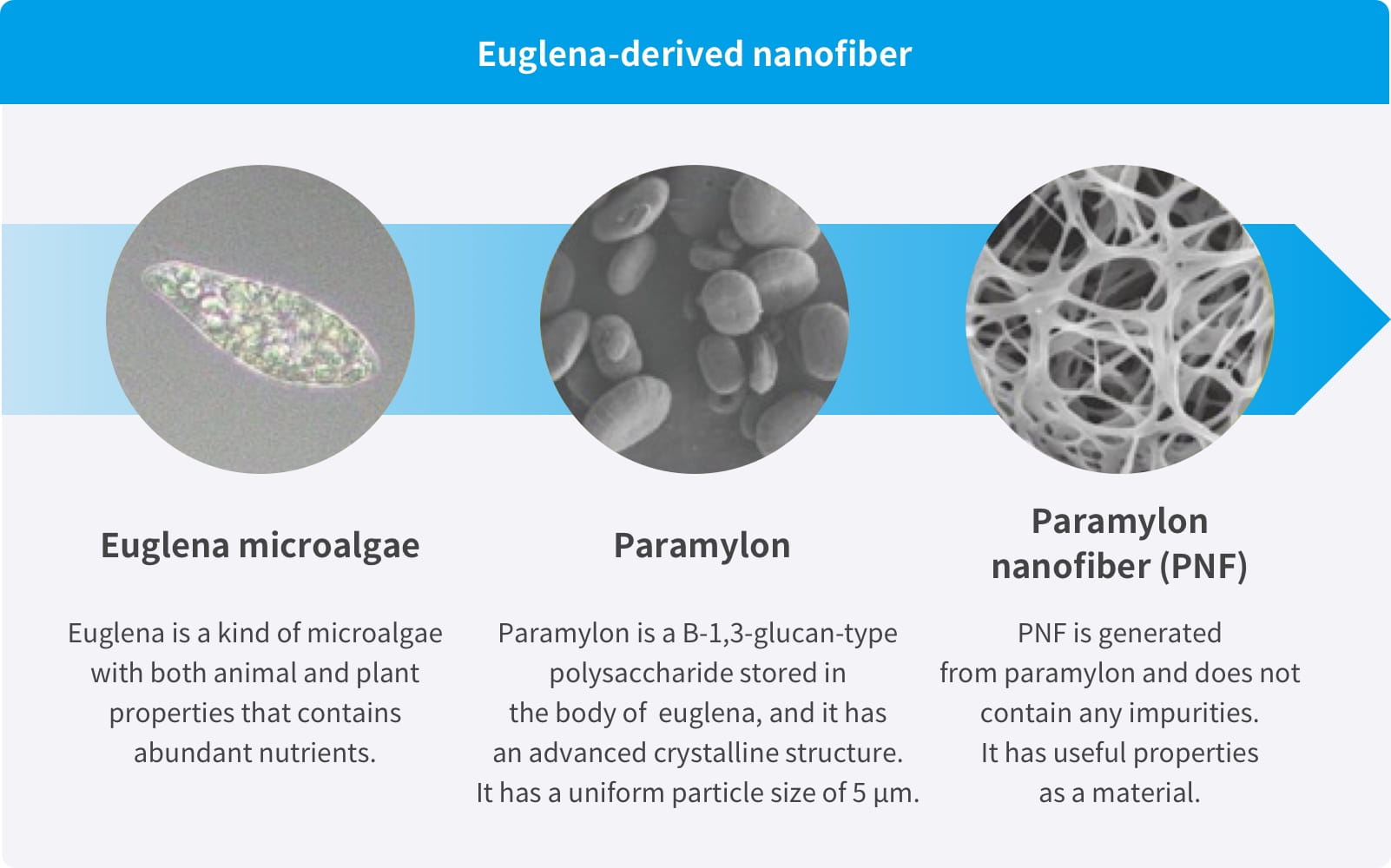

3. Sale of sustainable bio-derived nanofibers

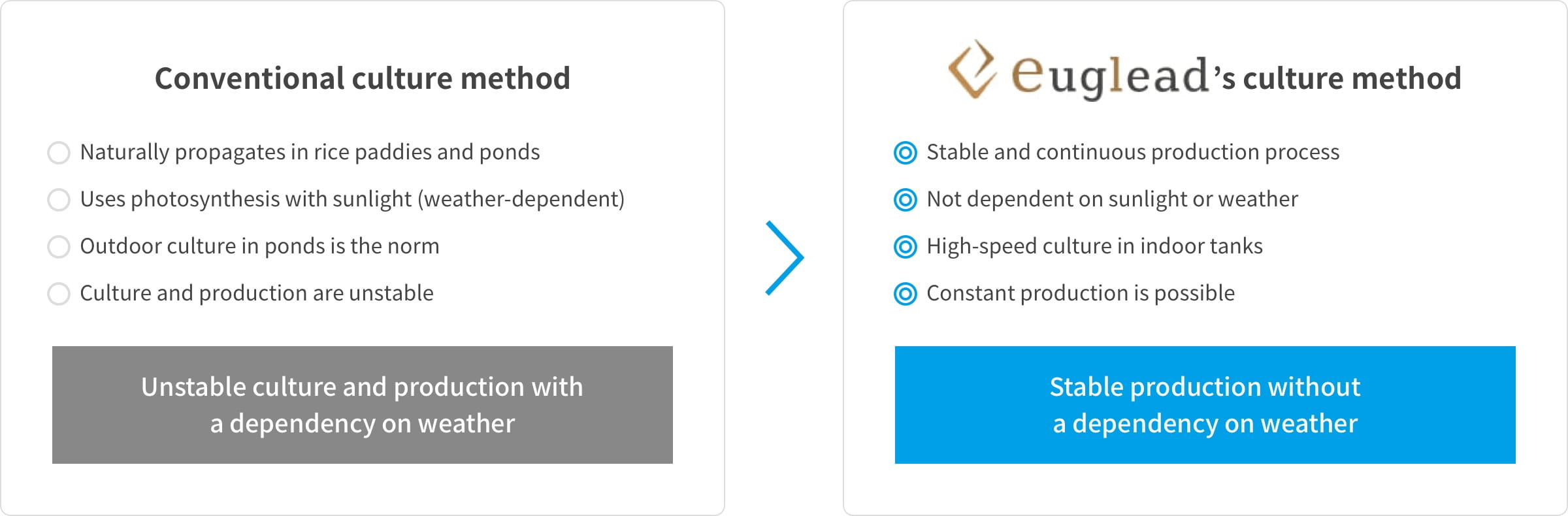

The Company invests in Euglead Inc., a manufacturer of paramylon nanofiber (PNF), a nanofiber derived from the euglena microalgae, and has a business tie-up related to the sale of PNF.

PNF, which is manufactured by Euglead Inc., is a naturally derived, eco-friendly nanofiber with a chemical structure and characteristics similar to cellulose nanofiber (CNF), whose demand is expected to grow as a plastic-reinforced composite. This natural material is gaining attention for its extremely wide range of applications, from plastic and rubber molding material that takes advantage of its high strength to inks and paints that impart thixotropic properties and electrode materials for fuel cells and other applications by making use of the large surface area due to the special shape of its complex triple helix structure.

CNF is a fiber made by loosening pulp to the 1/1 million mm level, but it is difficult to loosen uniformly, and its high cost is a drawback. Meanwhile, euglena-derived PNF has low fiber variation and is a single material, making it easy to design and manage, and it is one-fourth the cost of conventional CNF.

PNF is extracted from cultured euglena, making it a key material that contributes to a sustainable society with a low impact on the environment while opening the door to a decarbonized society. Utilizing our well-established sales network in the chemical and synthetic fiber fields, the Company aims to form a value chain in the biomass sector and advance the implementation of sustainable products in society by providing PNF as well as related equipment and facilities.

Related link: Euglead’s website https://euglead.co.jp/

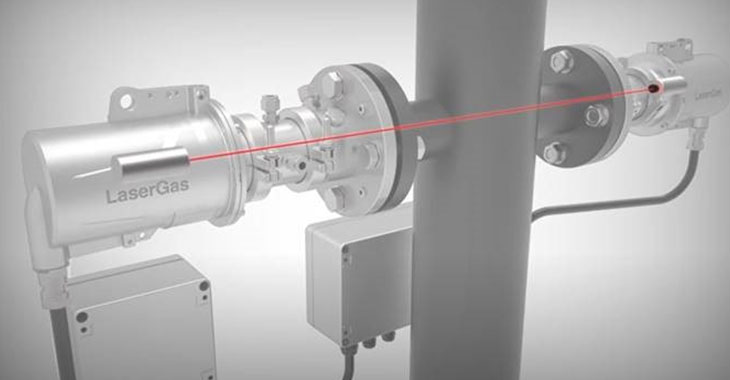

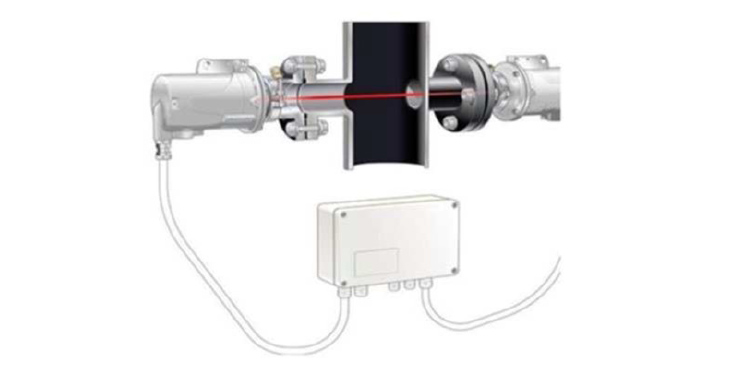

4. Laser-type gas analyzer for measuring toxic and corrosive gases

Laser-type gas analyzers are used to detect leaks of toxic and corrosive gases for management and control in production processes, environmental management, and ensuring worker safety in plants and work sites. In addition, as interest in a low-carbon society increases in recent years, there is growing demand to measure levels of oxygen in exhaust gas and control and manage combustion to increase combustion efficiency (and save energy). The Company handles laser-type gas analyzers from NEO Monitors AS in Norway. NEO Monitors AS is responsible for developing the world’s first laser-type gas analyzer in 1995 and is a specialty manufacturer with a worldwide network of distributors and the top global share for this technology. We have been the exclusive distributor of this technology in Japan for more than 20 years since NEO Monitors AS was established, and we use our sales network of over 2,000 companies to provide everything from sales to installation, adjustment, and after-sales service (including regular inspection, calibration, and maintenance support). In addition, we have multiple demo units in Japan and are able to quickly dispatch technicians for emergency on-site troubleshooting.

This product has the following features:

- Accurately measures a single gas or multiple gases at the same time

- Non-contact measurement of toxic and corrosive gases (Ensures safety of measuring operator)

-

Measures various types of gases

⇒Toxic gases (hydrogen fluoride, hydrogen cyanide, carbon monoxide) and corrosive gases (hydrogen sulfide) - Can be installed and used in environments up to 1,500°C and in dusty locations

- Instantly measures (within about 2 seconds)

- Low maintenance

- Can be installed at various sites

Related link: product introduction on Company’s website https://www.seika.com/product/gas/

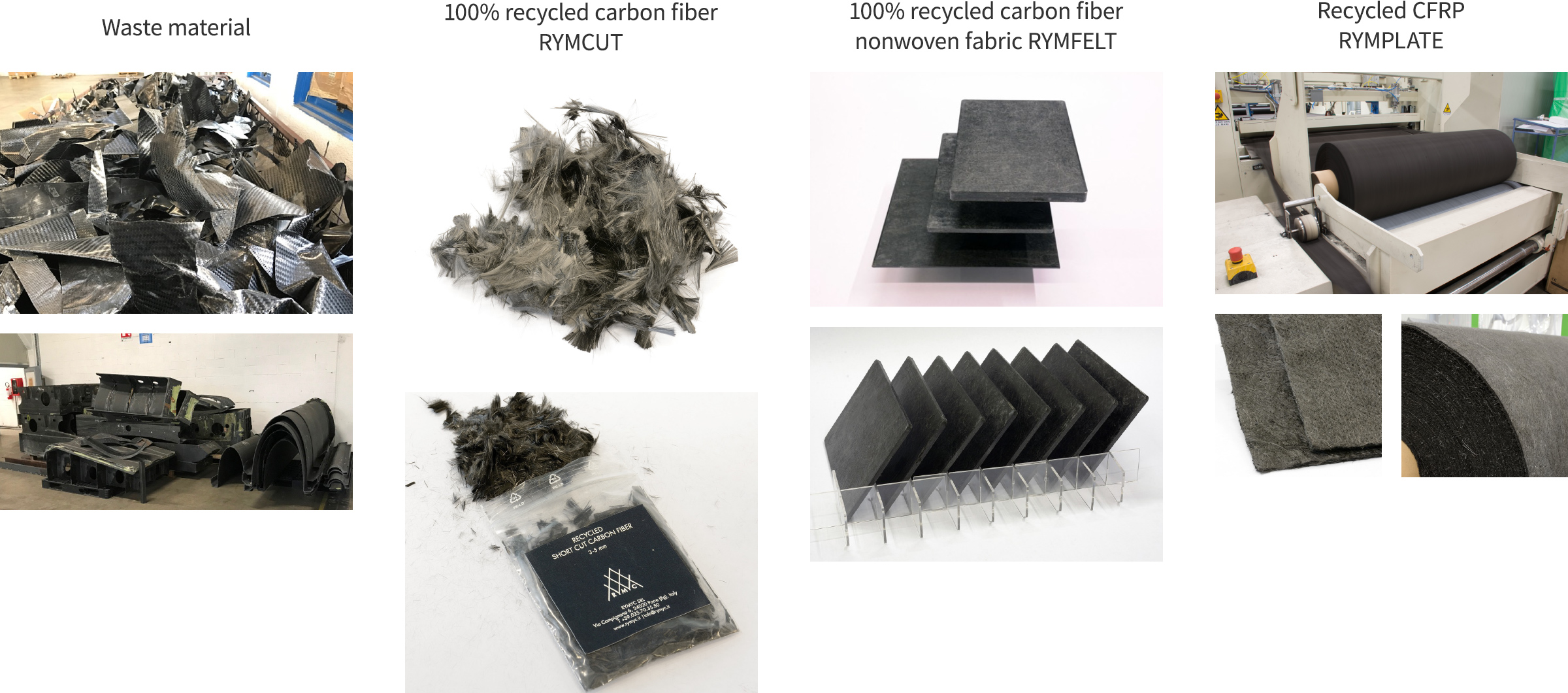

5. Sale of recycled carbon fiber using processing technology with a low environmental impact

Carbon fiber is a strong and lightweight material that weighs only one-fourth that of steel but is 10 times stronger, and it features excellent abrasion resistance, heat resistance, and thermal conductivity. As such, carbon fiber is used in a variety of applications, from automobiles and airplanes to sporting goods and structures, and it surrounds us in our daily lives.

However, until now, there was little progress in recycling carbon fiber reinforced-plastic (CFRP) that is generated from airplanes, automobiles, and other industrial applications, but recycling methods using thermal and chemical decomposition and other technologies have been studied, resulting in the creation of recycled carbon fiber (RCF), in which carbon fiber is re-extracted from CFRP processing scrap material, waste material after use, and expired prepreg.

Amid this situation, Seika Corporation reuses carbon fiber and provides new carbon fiber composite materials as the exclusive Asian distributor for Rymyc s.r.l. in Italy.

This company makes the most of its location in northern Italy, where vast amounts of high-quality CFRP end material are generated, to provide a stable supply of RCF that has been recycled using a proprietary method with low impact on the environment. Because they use a low-temperature, chemical-free recycling process instead of a method using solvents and other chemicals that can affect the environment, the physical properties of RCF compared to virgin carbon fiber (non-recycled carbon fiber) are better than those of other recovery methods. In addition, the advanced technology for processing nonwoven fabric makes it possible to process solid nonwoven fabric while controlling the fluff in conductive fiber, and the company can provide RCF nonwoven fabric that is easily formed and has excellent resin impregnation properties.

While the manufacture of carbon fiber produces large amounts of CO2 and there is currently no method for disposing of used carbon fiber other than landfill disposal, the Company will expand the use of RCF from Rymyc s.r.l., which has processing technology with low environmental impact, thereby contributing to creating a decarbonized society and circular economy.

Related link: Rymyc s.r.l. website https://www.rymyc.it/

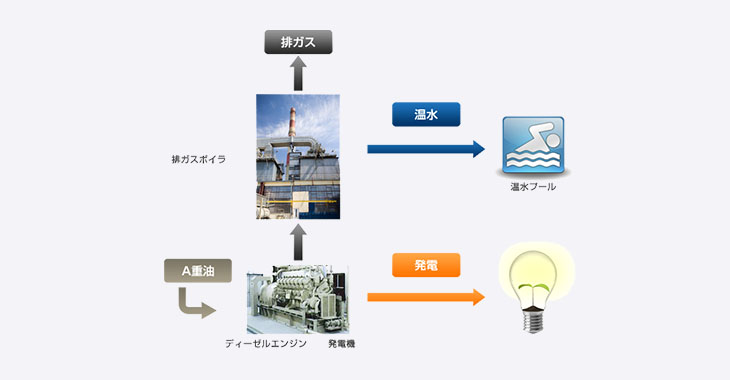

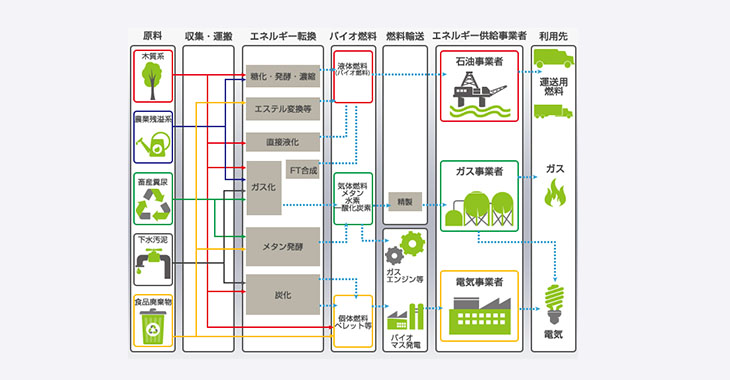

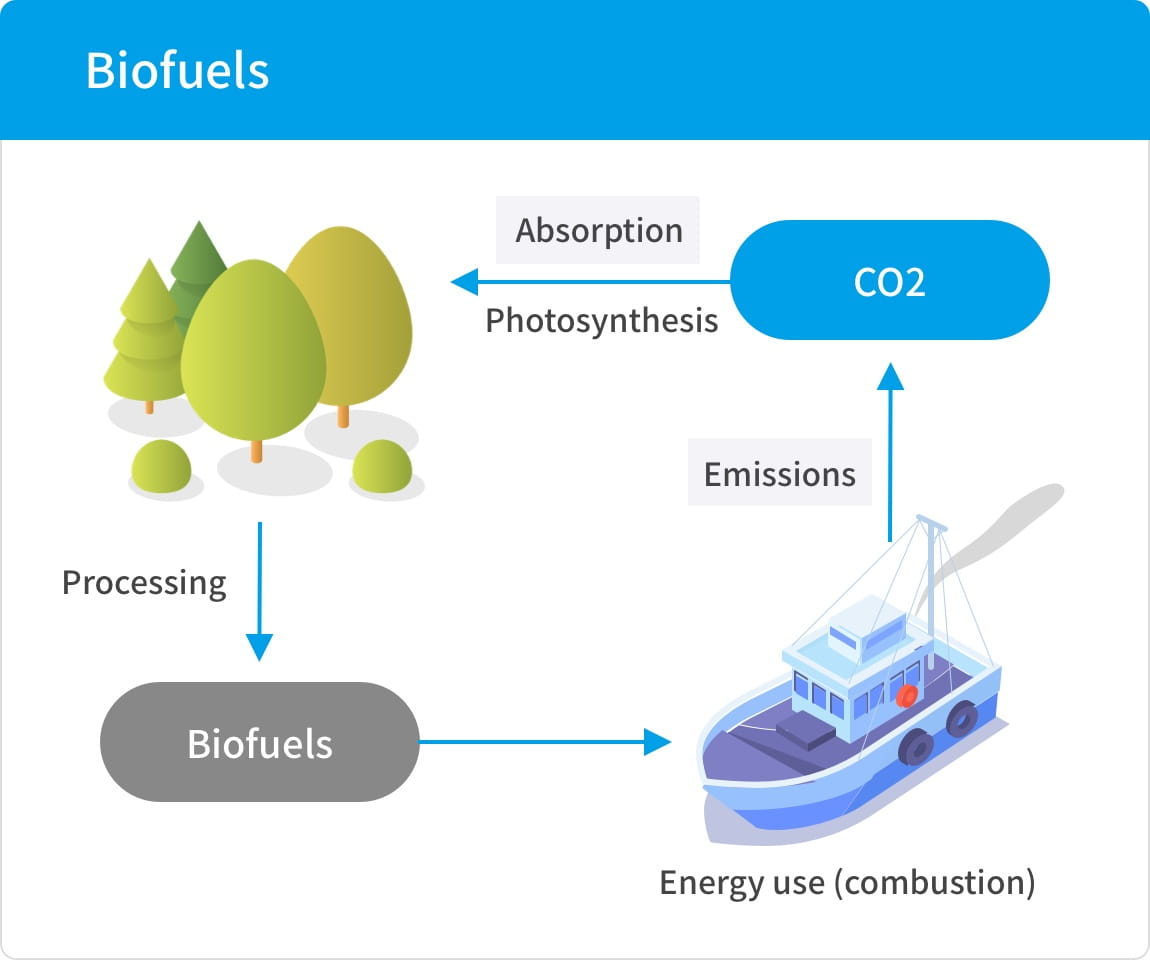

6. SUSTEO, a next-generation biodiesel fuel for fishing boat engines

Seika Daiya Engine also supports Euglena’s “GREEN OIL JAPAN” declaration aiming to make Japan an advanced biofuel nation, and the company promotes its business based on the SDG principles, especially Goal 14: Life Below Water, with the aim of pursuing biofuels for ships.

In 2005, Euglena successfully established the world’s first edible outdoor mass culture technology for the euglena microalgae on the Japanese island of Ishigaki, and in addition to the development and sale of functional foods, cosmetics, and other products utilizing euglena, chlorella, and other microalgae produced on Ishigaki Island, the company also conducts research and development on the commercial development of biofuels.

Biodiesel fuel, one of the company’s initiatives, is a next-generation fuel whose main raw material is used cooking oil and euglena microalgae, and it has excellent sustainability in terms of competition with food and low risk of deforestation. In addition, because the molecular structure is the same as diesel fuel (it is classified as diesel fuel under both JIS standards and the Act on the Quality Control of Gasoline and Other Fuels), it can be used in engines of existing vehicles that use diesel fuel, and its use can be efficiently expanded using the existing infrastructure without the need for large infrastructure costs, which is an issue with the transition to alternative energy sources such as hydrogen or electricity.

Seika Daiya Engine is making the following efforts to decarbonize diesel engines for fishing boats, its main product.

- Step1:Engine performance testing and understanding of performance for biodiesel fuel

- Step2:Exhibit at seafood shows

- Step3:Market testing of fishing boat diesel engines (using biodiesel fuel)

- Step4:Joint sponsorship with Shinmatsuura Fisheries Cooperative Association

Seika Daiya Engine is actively seeking partners to participate in market demonstration tests and contribute to decarbonization.

Related link: “Japan’s First Use of Biodiesel Fuel in Fishing Boat Engines” on the Seika Daiya Engine Co., Ltd. website(in Japanese)https://daiyaeng.co.jp/gallery/

Video of market demonstration testing of biofuel (YouTube)https://youtu.be/p-7qwKpegTE